This application required a robust solution for measuring air pressure within a submerged pipe during the testing of an innovative ship hull air lubrication system. The measurement was critical for analyzing system performance and efficiency but presented significant challenges due to the harsh operating environment and complex pressure dynamics. The goal was to find a pressure sensor capable of delivering accurate gauge pressure readings while being continuously submerged in seawater at variable depths.

- Measurement Type: Gauge air pressure inside a submerged pipe, relative to surface atmospheric pressure.

- Operating Environment: Continuous immersion in corrosive seawater at depths up to 10 meters.

- Pressure Range: A combined pressure of hydrostatic head plus an injected air pressure, totaling up to 1.3 bar gauge.

- Material Compatibility: Essential requirement for all wetted parts to be made from seawater-resistant materials, such as copper-nickel alloy (CuNiFe) and ceramic.

- Sensor Configuration: A vented cable design to provide a stable atmospheric reference for true gauge pressure readings, regardless of submersion depth.

A maritime engineering team, specializing in innovative ship efficiency technologies such as air lubrication systems, faced a critical measurement challenge during the component testing phase of a new system. The objective was to accurately determine the air pressure inside a submerged pipe that formed part of their air lubrication apparatus. This system is designed to reduce a vessel’s frictional drag by controllably releasing air beneath the hull. The test setup involved a pipe extending to variable depths, potentially between near surface and 9-10 meters in seawater. Air was injected through this pipe, and the pressure at a point near the injector needed precise monitoring.

The application presented several stringent requirements. Firstly, the sensor itself would be submerged in seawater, demanding exceptional corrosion resistance for both the sensor housing and wetted parts. The cable connection also needed to be completely waterproof for prolonged underwater deployment, with a required length of 20 metres to reach the surface monitoring equipment. The pressure to be measured was the gauge pressure of the air inside the pipe, relative to the ambient atmospheric pressure at the surface, not the local hydrostatic pressure. This internal pipe pressure was a sum of the hydrostatic back-pressure at the air outlet depth and an additional dynamic pressure, noted as a differential pressure (dP) of 0 to 0.4 bar, generated by the air injection system. Calculations based on a maximum depth of approximately 9 meters (roughly 0.9 bar hydrostatic pressure) plus the 0.4 bar injector pressure indicated a maximum internal gauge pressure of around 1.3 bar. Therefore, a sensor with a range comfortably accommodating this, such as 0 to 1.6 bar gauge, was necessary. Accuracy was also a key consideration for the detailed analysis and optimization of the air lubrication system’s performance. The output signal required was a standard 4-20 mA two-wire current loop.

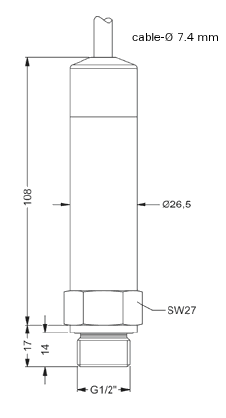

To address these demanding conditions, a solution centered around marine-approved pressure transmitters was proposed. Two specific series were identified as suitable, offering robust and precise measurement capabilities. The first option was the DMK457 series pressure transmitter. This sensor features a 0 to 1.6 bar gauge pressure range and an accuracy of 0.5% FS. Its construction includes a highly corrosion-resistant CuNi10Fe1Mn (copper-nickel alloy) and a ceramic Al2O3 diaphragm, both ideal for continuous seawater exposure. The electrical connection is made via a TPE cable specifically designed for permanent IP68 immersion. The sensor operates on a gauge reference, with a vent tube integrated within the cable, ensuring that measurements are always relative to the surface atmospheric pressure, effectively isolating the reading from the varying external hydrostatic pressure on the sensor body.

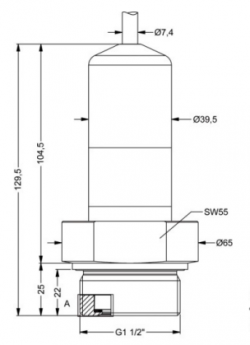

A second, higher-precision option was the LMK458 series, also a marine-approved transmitter. While often utilized for hydrostatic level measurement, its fundamental design as a robust pressure sensor made it equally suitable for this application, configured with a 0 to 1.6 bar gauge range. This series boasts a superior accuracy of 0.1% FS, providing finer resolution for detailed performance analysis of the air lubrication system. The LMK458 series similarly employs a copper-nickel alloy housing and a ceramic Al2O3 diaphragm for outstanding seawater compatibility, with FKM seals and a TPE-U submersible cable. Its gauge reference mechanism functions identically to the DMK457 series. The process connection for this series is a G1 1/2 male thread, offering a larger, potentially more robust, mounting alternative.

Both proposed product series provide the necessary 4-20 mA output and are designed for the harsh realities of marine deployment. The selection between them would allow the engineering team to balance accuracy requirements with specific mechanical integration preferences. The use of such specialized instrumentation enables the engineers to gather reliable data on the air injection pressure, which is vital for validating system design, optimizing energy consumption of the air compressors, and ensuring the overall effectiveness of the air lubrication technology in real-world operational depths. The ceramic diaphragm offers excellent resilience against any particulates in the air system or potential minor backflow, while the robust copper-nickel alloy wetted parts ensure long-term stability in the aggressive saltwater environment.

DMK457 Submersible Seawater Resistant Air Pressure Transmitter

- SKU ID: s1-dmk457-0013

- Pressure Range: 0 to 1.6 bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4 – 20 mA, 2-wire

- Accuracy: 0.5% FS

- Electrical Connection: TPE cable IP68 seawater compatible housing (permanent immersion)

- Cable Length: 20

- Cable Length Units: metres (m)

- Process Connection Material: CuNi10Fe1Mn Seawater Compatible

- Process Connection: G1/4 DIN3852

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

LMK458 Submersible Seawater Resistant Air Pressure Transmitter

- SKU ID: s1-lmk458-0035

- Pressure Range: 0 to 1.6 bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.1% FS

- Installation Type: G1 1/2 male screw-in version

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 99.9%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 20

- Cable Length Units: Metres (m)