High-pressure calibration systems are essential tools for ensuring the accuracy and reliability of high-pressure measurement instrumentation in demanding industrial and research environments. These systems utilize pneumatic or hydraulic pumps to generate precise calibration pressures, enabling verification and testing of various high-pressure sensors, gauges, and indicators.

3000 psi high pressure calibration hand pump and gauge - High pressure hand pump and electronic digital pressure gauge for calibrating pressures up to 3000 psi max.

3000 psi high pressure calibration hand pump and gauge - High pressure hand pump and electronic digital pressure gauge for calibrating pressures up to 3000 psi max.

LEX1 (Ei) High Accuracy Digital Pressure Gauge

LEX1 (Ei) High Accuracy Digital Pressure Gauge DM01-500-HD High Range Digital Pressure Gauge

DM01-500-HD High Range Digital Pressure Gauge 100 bar / 1,500 psi Hand Operated Pressure Calibration Pump – ADT918

100 bar / 1,500 psi Hand Operated Pressure Calibration Pump – ADT918 Pressure Calibrator for Pressure Transmitter Calibration – ADT672

Pressure Calibrator for Pressure Transmitter Calibration – ADT672

200bar/3000psi Hand Operated High Air Pressure Test Pump – ADT920

200bar/3000psi Hand Operated High Air Pressure Test Pump – ADT920 2000 bar pressure calibration pump and digital test gauge

2000 bar pressure calibration pump and digital test gauge 2,500 bar / 37,500 psi Hydraulic Pressure Calibration Pump – ADT949

2,500 bar / 37,500 psi Hydraulic Pressure Calibration Pump – ADT949 ADT681 Digital Pressure Gauge

ADT681 Digital Pressure Gauge

140 bar / 2,000 psi Hand Operated Air Pressure Test Pump – ADT919A

140 bar / 2,000 psi Hand Operated Air Pressure Test Pump – ADT919A PGS1000 Handheld Hydraulic Pressure Test Pump

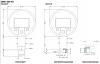

PGS1000 Handheld Hydraulic Pressure Test Pump PGS700 High Pressure Calibration Hand Pump

PGS700 High Pressure Calibration Hand Pump

Find out more about High Pressure Range Calibrators to determine which product options and capabilities will best meet your application requirements.

High-pressure calibration systems play a crucial role in various industries and research fields where accurate pressure measurement is paramount. These systems provide a reliable means of verifying and calibrating high-pressure measurement devices to ensure their performance and compliance with industry standards.

Key Components:

- High-Pressure Pump: The core component of a high-pressure calibration system is a high-pressure pump, which can be either pneumatic or hydraulic. Pneumatic pumps use compressed gas to generate pressure, while hydraulic pumps use pressurized liquid. The choice of pump depends on the specific pressure range and application requirements.

- Pressure Gauge or Indicator: A high-accuracy pressure gauge or indicator is used to measure and display the generated pressure. This gauge serves as the reference standard for calibrating the device under test.

- Fittings and Connections: High-pressure fittings and connections are used to connect the pump to the device under test. These fittings ensure a leak-free and secure connection to maintain the integrity of the calibration process.

- Pressure Relief Valve: A pressure relief valve is an essential safety component that prevents overpressure situations. It automatically releases pressure if it exceeds a predetermined limit, protecting the equipment and personnel.

Instrument Types

- Pneumatic Calibrators: These calibrators utilize compressed gas, usually nitrogen or air, to generate high pressures. They are often preferred for their cleanliness and ease of use, making them suitable for applications in cleanrooms or laboratories. Pneumatic calibrators are commonly used for calibrating pressure gauges, transducers, and switches.

- Hydraulic Calibrators: Hydraulic calibrators employ a liquid medium, such as oil or water, to generate high pressures. They are known for their ability to produce extremely high pressures and maintain stability over extended periods. Hydraulic calibrators are commonly used for calibrating high-pressure gauges, transmitters, and pressure relief valves.

- Portable Calibrators: Portable high-pressure calibrators are compact and lightweight, making them suitable for field applications. They typically include a built-in pump and pressure gauge, allowing for on-site calibration of pressure instruments.

- Benchtop Calibrators: Benchtop high-pressure calibrators are larger and more versatile than portable calibrators. They offer higher accuracy and a wider pressure range, making them suitable for laboratory and workshop use.

- Modular Calibrators: Modular high-pressure calibrators consist of separate modules that can be combined to create a customized calibration system. This modularity allows for flexibility and scalability to meet specific application needs.

Applications

High-pressure calibration systems are essential in the hydraulics industry for calibrating pressure sensors, transducers, and gauges used in hydraulic machinery and equipment. Applications include:

- Manufacturing: Calibration of pressure sensors in hydraulic presses, injection molding machines, and other hydraulically powered manufacturing equipment.

- Construction: Verification of pressure gauges in hydraulic excavators, cranes, and other heavy machinery used in construction projects.

- Agriculture: Calibration of pressure sensors in hydraulic systems of tractors, harvesters, and other agricultural equipment.

- Material Handling: Ensuring the accuracy of pressure gauges in hydraulic forklifts, aerial work platforms, and other material handling equipment.

Accurate pressure measurement in hydraulic systems is vital for ensuring safe operation, preventing equipment damage, and optimizing performance. High-pressure calibration systems provide a reliable means of verifying and maintaining the accuracy of hydraulic pressure measurement devices, contributing to the overall efficiency and reliability of hydraulic systems in various industries.

Other industries which have use for high pressure calibration equipment include:

- Oil and Gas Industry: In oil and gas exploration and production, high-pressure calibration systems are used to calibrate pressure sensors in drilling operations, pipeline monitoring, and wellhead control systems. Accurate pressure measurement is critical for ensuring safety and optimizing production processes.

- Process Industry: In chemical processing, power generation, and other process industries, high-pressure calibration systems are employed to calibrate pressure transmitters, transducers, and gauges used in process control and monitoring. Precise pressure measurement is essential for maintaining product quality, process efficiency, and safety.

- Aerospace Industry: High-pressure calibration systems are utilized in the aerospace industry to calibrate pressure sensors in aircraft hydraulic systems, engine test stands, and wind tunnel experiments. Accurate pressure measurement is vital for ensuring flight safety and optimizing aircraft performance.

- Research and Development: In research laboratories and testing facilities, high-pressure calibration systems are used to calibrate pressure sensors and instruments used in various experiments and studies. Precise pressure measurement is crucial for obtaining reliable and accurate research data.

Selection Considerations

When selecting a high-pressure calibration system, several factors should be considered:

- Pressure Range: The pressure range of the system should be compatible with the pressure range of the devices being calibrated.

- Accuracy: The accuracy of the system should be higher than the accuracy of the devices being calibrated.

- Application: The type of application and environment will influence the choice of system, such as portable for field use or benchtop for laboratory use.

- Features: Additional features such as data logging, automation, and communication capabilities may be desirable depending on the specific needs.