General purpose industrial pressure transmitter with a 4-20mA current loop or amplified voltage output available in range from -1 to +1 barg up to 1000 barg.

The TK industrial pressure transmitter has a robust Inox AISI430F stainless steel diaphragm with screen printed thick film strain gauges providing a low cost durable construction for punishing high duty applications such as pneumatic compressors, hydraulic presses, hydraulic systems, trains, construction vehicles, trucks, system integration, panel builders and control systems.

Product Parameters

- Pressure Ranges: +/-1 up to 1000 bar gauge and compound pressure

- Accuracy: 0.5% FS or improved 0.25% FS

- Output Signal: 4 to 20 mA current or amplified voltage

- Media Operating Temperature: -40 to 105 DegC

- Electrical Connections: Plug and cable options with IP65 to 67 protection rating

- Pressure Connections: BSP, NPT, UNF and metric threads, male and female

- Media Compatibility: Stainless steel 17-4ph

- Dimensions: 26.5mm dia x 84mm long (total length without electrical mating connector)

- Weight: 110g

Product Description

Applications

The TK industrial pressure transmitter is a budget pressure sensor with a moderate accuracy developed for pneumatic automation & hydraulic system applications such as CNC machinery, packaging machines, hydraulic press and robotics, where reliability, robustness and affordability are valued higher than precise pressure measurements.

The TK thick film pressure sensor is available with a wide choice of compound pressure ranges for the combined measurement of vacuum and pneumatic pressures from -1 to 1 bar up to 10 bar gauge. Due to the relative high thickness of the pressure sensing diaphragm and absence of an oil filled isolation diaphragm the TK thick film pressure sensor is suited to low to medium range hydraulic systems up to 1000 bar pressure.

Sensor Technology

The main ingredient for ensuring reliability is the TK pressure sensor diaphragm which is machined out of one piece of 17-4 PH stainless steel.

There are no welds or adhesive bonds involved in integrating the pressure sensing diaphragm with its retaining module, which is good for repeatability of performance and long term pressure integrity.

Thick film strain gauges are screen printed onto the reverse side of the sensing diaphragm to form a Wheatstone bridge circuit. This involves building up an insulating layer to isolate the strain gauge circuit from the metal diaphragm and a conductive layer for making connections between the strain gauges prior to adding the final resistive layer.

Build Design

The sensor module is then ready to be welded to its pressure connection which is the only pressure containment weld required in the construction which helps to extend the pressure sensors MTBF (mean time between failures).

The mV output signal generated by the pressure sensor module is then processed by digitally programmable electronics to provide an amplified 4-20mA signal or voltage signal output. A pressure measurement accuracy of ±0.5% full scale is achieved as standard with the TK thick film pressure sensor internal signal conditioning and for enhanced measurement accuracy an optional ±0.25% FS can be specified.

The pressure transmitter is finished off with a choice of electrical connections with environmental protection of IP65, IP66 or IP67 depending on how wet the machinery gets externally, which include a DIN 43650 plug, Amphenol military bayonet and M12 connector.

Product Help

TK-E-1-E-B03U-M-V

What is the specification for part number TK-E-1-E-B03U-M-V?

- SKU ID: s1-tk-0001

- Pressure Range: 3

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA

- Electrical Connection: DIN43650A standard plug IP65

- Optional Mating Connectors: Not required

- Process Connection: G1/4 male (DIN3852-A)

Connecting and powering 4-20mA version

For the signal output of 4 to 20mA, how is the sensor connected to a voltage source and what is the required voltage to provide the output current?

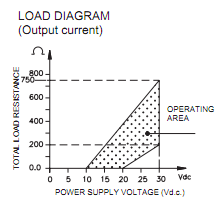

Your power supply, signal conditioning unit and the transmitter are all connected together in a series loop, and the signal is the resulting current of the circuit which is controlled by the transmitter. The required supply voltage for the pressure sensor is between 10…30 VDC, but it is necessary to also allow for any voltage drop through any load resistance in the circuit. The graph shows the required power supply to operate the transmitter for different load resistance.

Your power supply, signal conditioning unit and the transmitter are all connected together in a series loop, and the signal is the resulting current of the circuit which is controlled by the transmitter. The required supply voltage for the pressure sensor is between 10…30 VDC, but it is necessary to also allow for any voltage drop through any load resistance in the circuit. The graph shows the required power supply to operate the transmitter for different load resistance.

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the TK Industrial Pressure Transmitter in your application and request a quote.