A vehicle manufacturer needed to streamline its end-of-line (EOL) brake testing process. The existing setup, which used traditional wired pressure transmitters, was inefficient for their fast-paced production line, creating setup delays and cable management issues. They required a robust wireless solution capable of monitoring five separate points on the truck’s brake reservoirs simultaneously, matching the accuracy of their existing ceramic-cell sensors and integrating with their current data acquisition system.

- Application: End-of-line (EOL) brake system testing for truck manufacturing.

- Challenge: Replacing cumbersome wired sensors to improve efficiency within a 9-minute takt time.

- Requirement: Simultaneous, real-time pressure measurement from 5 points during a 5-minute test cycle.

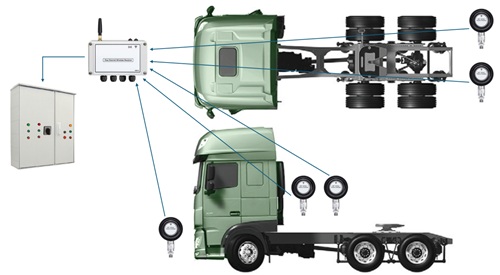

- Solution: A 5-channel wireless system using IWPT series transmitters and an IWR-5 receiver.

A manufacturer of large trucks identified a significant bottleneck in its End-of-Line (EOL) quality control process. The application involved testing the vehicle’s brake system, requiring simultaneous pressure measurements from five different reservoirs. This test was conducted within a fast-paced production environment with a total “takt time” of nine minutes per vehicle. The actual brake test, however, lasted for a 5-minute window within that cycle.

The facility’s manufacturing engineers were using conventional cabled pressure transmitters with ceramic measuring cells. This wired setup proved cumbersome, requiring technicians to connect multiple tubes or cables to the truck’s reservoirs for each test. This process was inefficient, increased the risk of connection errors, and introduced potential trip hazards and cable maintenance issues on the busy production floor.

The primary requirement was to replace this setup with a fully wireless system to improve operational efficiency. The solution needed to measure pressures up to 10 bar and provide data with an accuracy comparable to their existing sensors. A critical technical challenge was the need for high-speed, “real-time” data acquisition. The engineers specified a data update rate of 0.5 seconds (2 Hz) to capture a clear pressure profile during the 5-minute test. This high-speed transmission was only needed during the test, not for the full nine-minute cycle. Additionally, the new wireless sensors had to physically interface with the M22x1.5 male threads on the vehicle’s reservoirs.

The solution provided consisted of five IWPT series wireless pressure transducers paired with a single IWR-5 five-channel wireless receiver.

The IWPT series transducers were specified with a 0-16 barg pressure range, providing a safe operating margin for the 10-bar application. These transmitters utilize a piezo-resistive ceramic sensor, offering the same reliable sensing technology the customer’s engineers were familiar with. While the standard transducer features a 1/4″ BSP process connection, this was easily resolved by using a standard M22x1.5 to 1/4″ BSP mechanical thread adaptor, allowing direct installation onto the reservoirs.

The IWR-5 receiver was the key to integrating the system into the plant’s existing control architecture. As a five-channel unit, it could simultaneously manage the data from all five transducers. A major benefit for the process engineers was that the IWR-5 provides five independent analog outputs. This allowed the new wireless system to function as a direct, “drop-in” replacement for the old wired sensors, feeding the pressure data (as 4-20mA or 1-5V signals ) straight into their existing PLC or data acquisition system for test validation.

To meet the high-speed data requirement, the system was specially configured for a 0.5-second transmission update rate. This fast rate would typically reduce sensor battery life, but an intelligent power-saving feature was employed. The transducers were set to transmit at the high-speed 0.5s rate only when the IWR-5 receiver is powered on. The customer simply powers the receiver (which uses a 12-32 Vdc supply ) at the start of the 5-minute test and powers it off at the end. When the receiver is off, the transducers automatically reduce their transmission rate, conserving battery life during the idle portion of the takt time. This “on-demand” transmission provided the real-time data required by the application while still maximizing the operational life of the transducers’ batteries.

IWPT Wireless Pressure Sensor with IWR-5 Five Channel Receiver

- Part No: IWPT-G1602-00, IWR-5

- Wireless Transmitters: Pressure Sensor

- Process Connection: 1/4 BSP male

- Pressure Ranges: 16 bar g

- Wireless Receivers: Five channel 1-5V or 4-20 mA output

- Optional Extras: 0.5 second update rate when receiver on