Monitoring the differential pressure across an Air Handling Unit’s cooling coils is a direct and effective method for assessing operational efficiency and scheduling predictive maintenance. This application required a precise, multi-range differential pressure sensor with an automatic zeroing function. The integration required a modified wiring plan to accommodate the sensor’s power requirements, which exceeded that of the customer’s existing data acquisition module.

- Application: Measuring low-pressure drop (0-4 mbar) across AHU cooling coils.

- Challenge: Integrating a high-spec transmitter with the customer’s lower-power data logger.

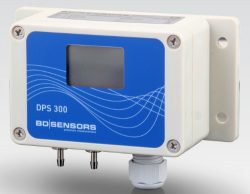

- Product Solution: DPS 300 3-wire transmitter with automatic zeroing.

- Integration Solution: An external 30V DC power supply was used to meet the transmitter’s specific requirement of >26V DC for the automatic zeroing feature, with the 4-20mA signal fed separately to the customer’s module.

- Benefit: Achieved a highly accurate, drift-free measurement system by adapting the integration approach to support an advanced sensor.

Monitoring the operational health of Air Handling Units (AHUs) is a critical task in maintaining building efficiency and air quality. A key performance indicator for an AHU is the pressure drop across its internal components, such as filters and cooling coils. An increase in this differential pressure often signifies a blockage from dust, debris, or ice formation, leading to reduced airflow, decreased thermal efficiency, and higher energy consumption as fans work harder to compensate. A customer required a robust solution to continuously monitor this pressure difference across the cooling coils within their AHU, specifying that the sensor must integrate with their existing data monitoring system.

The core of the customer’s challenge was to find a pressure-sensing device that could accurately measure very low pressure differentials in the millibar range and provide a standard industrial output signal compatible with their chosen data acquisition module. The solution had to be reliable for long-term, continuous operation and include an automatic zeroing function to eliminate sensor drift over time.

For this application, the DPS 300 series differential pressure transmitter was the ideal instrument. This transmitter is specifically developed for demanding HVAC applications. The selected model featured switchable measuring ranges of 0-4 mbar and 0-2.5 mbar, providing flexibility for the application. The installation is straightforward: one pressure port is connected via flexible tubing to the upstream side of the cooling coil, and the second port is connected to the downstream side. For optimal performance and to prevent any potential for condensation to accumulate in the impulse lines, the device is designed for vertical mounting with the pressure ports pointing downwards. The included automatic zero adjustment feature periodically re-zeros the sensor, ensuring continued accuracy without the need for manual intervention—a critical requirement for a permanent monitoring installation.

The selected DPS 300 is a 3-wire device with multiple switchable outputs, including 0-10V and 4-20mA, offering significant versatility. A crucial part of the integration was ensuring compatibility with the customer’s data acquisition hardware, a UA20-B series USB converter. An initial review determined that the UA20-B module’s internal 12V DC power output was insufficient for this specific configuration. The 3-wire DPS 300 with the automatic zeroing option requires a dedicated power supply of more than 26V DC, within its operational range of up to 32V DC. The solution involved a revised wiring approach where the DPS 300 transmitter was powered by a separate, external 30V DC power supply. The transmitter’s 4-20mA signal output was then wired to the input terminals of the customer’s UA20-B module. In this configuration, the module functions purely as a data measurement and conversion device, while the power for the sensor is handled independently. This approach successfully overcame the power incompatibility, allowing the customer to leverage their existing hardware while benefiting from the advanced features, such as automatic zeroing, of the more capable 3-wire transmitter.

DPS300 Adjustable Range & Output DP Transmitter with Auto-Zero

- SKU ID: s1-dps300-0001

- Part No: 815-0040-3Z-0-G-C-1-Y00-M-600

- Pressure Range: 0 to 4 / 0 to 2.5 (2 switchable ranges)

- Units: mbar

- Range Type: Differential (0 to +P)

- Output Signal & Supply Type: 0 to 10 Vdc / 0 to 20 mA / 0 to 5 Vdc / 4 to 20 mA (3 wire, 4 switchable outputs)

- Output Options: Linear

- Supply Voltage: 24-32Vdc

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M16 x 1.5 cable gland

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Air

- Optional Extras: Integral LCD readout, Automatic zeroing