A food processing client involved in the manufacturing of coconut powder required a precise and reliable method for monitoring the pressure within their drying towers. The quality of the final product is highly dependent on maintaining a specific negative pressure, or depression, inside the tower relative to the ambient atmospheric pressure. This controlled vacuum environment facilitates the evaporation of moisture at lower temperatures, which is crucial for preserving the delicate flavour, aroma, and nutritional quality of the coconut powder.

The application required a solution that could not only measure a very low-pressure range but also provide control outputs to manage the process and integrate with the existing plant-wide control system.

- Challenge: Accurately measure a low-level vacuum (depression) in a potentially hot and humid drying tower environment.

- Process Parameter: 0 to 200 mmH2O differential pressure.

- Essential Functionality: Provide integrated switch contacts for process control and alarms.

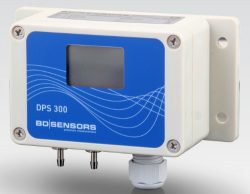

- Solution: A DPS 300 series low-range differential pressure transmitter with configurable switch outputs.

The core of the customer’s challenge was to precisely measure and control the drying tower depression. This measurement is the differential pressure between the inside of the drying chamber and the outside atmosphere. The required measurement range was specified as 0 to 200 millimetres of water column (mmH₂O), which is equivalent to approximately 20 millibar. This low-pressure measurement is critical; too much vacuum could lead to overly rapid drying or carry-over of fine powder, while insufficient vacuum would extend drying times and potentially compromise product quality by requiring higher temperatures.

The client needed a standard 4-20mA analogue signal output for logging and monitoring purposes within their central control system. Furthermore, a critical requirement was the inclusion of local switch contacts. These switches would be used to trigger alarms or activate control elements, such as adjusting fan speeds or heater outputs, if the tower depression deviated from the predetermined optimal setpoints. This automated control is essential for maintaining process consistency and efficiency.

The proposed solution was the DPS 300 series differential pressure transmitter, a device specifically designed for measuring low pressures in dry, non-aggressive gases like air. The recommended installation involves mounting the instrument in a clean and cool location away from the process heat. Flexible tubes are then used to connect the instrument’s pressure ports to the relevant points: the negative pressure port is connected to a representative location on the drying tower, and the positive pressure port is left open to the local atmosphere, which serves as the stable reference pressure. This remote mounting method uses the tubing to effectively dissipate heat, ensuring the process air cools before reaching the sensor and protecting the instrument from high temperatures.

DPS300 DP Transmitter with 2 PNP Open Collector Switch Contacts

- Pressure Range: 0 to 200

- Units: mmH2O

- Range Type: Differential (0 to +P)

- Output Signal & Supply Type: 4 to 20 mA (2 wire)

- Output Options: Linear

- Supply Voltage: 11-32Vdc

- Accuracy (linearity only): 0.5% full scale

- Electrical Connection: M16 x 1.5 cable gland

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Air

- Optional Extras: Integral LCD readout