Maintaining operational integrity within the high-demand environment of a data center is paramount. A crucial component of this is the management of the facility’s cooling infrastructure, specifically the chilled water circulation systems. An operator of a data center facility required a robust and modern solution for monitoring pressure within these chilled water loops to ensure consistent performance and prevent equipment failure. The solution involved implementing a pressure sensor with a direct digital communication protocol to integrate seamlessly into their facility-wide monitoring system.

- Application: Chilled water pressure monitoring in a data center.

- Challenge: Need for reliable, networkable sensors for integration into a modern Building Management System (BMS).

- Measurement Range: 0 to 10 bar gauge pressure.

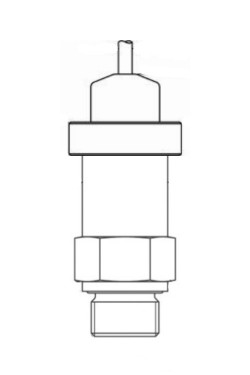

- Solution: DCT 531 serial interface pressure sensor with RS485 Modbus RTU.

The thermal management of a data center is a mission-critical task where even minor deviations can lead to server overheating and catastrophic downtime. Chilled water cooling loops are the lifeblood of this operation, circulating coolant to computer room air handlers (CRAHs) to dissipate the immense heat generated by IT equipment. To guarantee the efficiency and reliability of this system, a facility management team needed to accurately monitor the pressure at various points within the chilled water pipework. This data is essential for verifying pump performance, ensuring adequate flow to all cooling units, and providing early warnings of potential leaks or blockages. The application required a solution that could move beyond traditional analog signals and integrate directly into a sophisticated, centralized control and monitoring network.

The key requirement was for a pressure sensor with a digital communication output, specifically using the Modbus RTU protocol over an RS485 interface. This approach allows multiple sensors to be networked on a single data bus, significantly reducing the complexity and cost of wiring compared to individual point-to-point connections for analog sensors. The chosen pressure range of 0 to 10 bar gauge is typical for the operational parameters of these secondary cooling circuits. Furthermore, the wetted materials needed to be compatible with the treated water used in the system, demanding high-grade stainless steel and durable FKM seals to prevent corrosion and ensure a long service life.

The DCT 531 serial interface pressure sensor was identified as the ideal solution to meet these specific demands. Its native RS485 Modbus RTU output provides a direct digital data stream, ensuring noise-immune and reliable communication from the plant room floor back to the central BMS. This digital integration simplifies system architecture and provides clearer, more accurate data for trend analysis and automated control strategies. The sensor’s construction, featuring a stainless steel 1.4435 (316L) diaphragm and a robust process connection, offers excellent compatibility with the fluid media.

For an environment that operates 24/7, long-term reliability is non-negotiable. The DCT 531 series is engineered for excellent long-term stability, specified at less than or equal to

±0.1% Full Scale Output per year, which minimizes measurement drift and reduces the frequency of recalibration. Its high ingress protection rating of IP67 ensures it is fully protected from dust and moisture ingress within the mechanical plant room environment. By deploying this serial interface pressure sensor, the data center can maintain precise control over its critical cooling infrastructure, ensuring optimal operating conditions and safeguarding server uptime.

DCT 531 Modbus RTU Pressure Sensor

- Part No: DC7-1002-L5-3-TA0-100-1-000

- Pressure Range: 0 – 10 Bar G

- Output: RS 485

- Supply Voltage: 9 – 32V dc

- Electrical Connection: Cable Gland including 2 mtr PVC Cable

- Process Connection: G 1/2″ DIN 3852

- Process Connection Material: Stainless Steel 1.4571 (316Ti)

- Seal Material: FKM

- Diaphragm Material: Stainless Steel 1.4435 (316L)

- Accuracy (NL&H): 0.35% FSO IEC 60770

- IP Rating: 65

- Media Temperature: -25 to +125°C

- Operating Temperature: -25 to +85°C

- Special Options: None

- Approvals: None