A pharmaceutical facility required a reliable and compliant environmental monitoring system for six cleanrooms. The solution needed to measure and help control differential air pressure, temperature, and relative humidity, providing continuous analogue signals to a Building Management System (BMS) for proportional control, while also logging all data centrally for auditing purposes. The final system integrated room-specific transmitters into a networked data acquisition system, successfully meeting all technical and operational requirements.

- Monitoring and control of differential pressure, temperature, and humidity.

- Cabled sensors for temperature and humidity allowing for display outside the cleanroom.

- Dual 4-20mA analogue outputs for proportional control via a Building Management System (BMS).

- Centralised data logging from multiple rooms via an RS-485 Modbus network.

A project manager for a pharmaceutical facility required a comprehensive environmental monitoring and control system for six cleanrooms. Maintaining precise environmental conditions is critical in pharmaceutical applications to prevent contamination, ensure product stability, and comply with regulatory standards. The primary requirement was to continuously monitor and control differential air pressure, ambient temperature, and relative humidity within each room.

A key technical challenge was the need for proportional control of thyristor heaters via a central Building Management System (BMS), as simple on-off control was inadequate for their process. This necessitated instrumentation that could provide continuous analogue output signals. The customer specified a preference for 4-20mA outputs for both temperature and humidity to be fed into their BMS, which would then modulate the heating and cooling systems.

For operational convenience and to maintain the integrity of the cleanroom environment, the temperature and humidity sensing elements needed to be located inside the cleanrooms, while the instrument displays had to be mounted externally at the entrances. This called for a solution with cabled probes. Furthermore, all data from the network of sensors across the multiple rooms needed to be aggregated and recorded by a central data logger for quality assurance and compliance auditing.

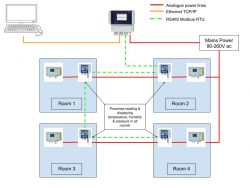

To meet these requirements, a distributed monitoring system was proposed, comprising individual room sensors for each parameter, all networked to a central multichannel data logger.

For monitoring temperature and humidity in each of the six rooms, the ProSens series of climate monitors was selected. A significant feature of the ProSens is its availability with a remote cable probe , which directly addressed the customer’s need to separate the sensing element from the display. This allows the probe to be installed in the critical area within the cleanroom, while the main unit with its clear LCD is wall-mounted outside for easy access and observation without breaching the controlled environment. Crucially, the ProSens was configured with two analogue outputs , providing the requested independent 4-20mA signals for both temperature and humidity. These signals are fed directly to the customer’s BMS, enabling precise, proportional control of their heating and cooling equipment.

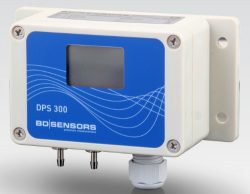

To manage the critical cleanroom pressure cascades, a DPS 300 series differential pressure transmitter was specified for each room. This instrument is specifically designed for low-pressure HVAC and cleanroom applications , making it ideal for monitoring the subtle but vital pressure differences. The unit’s user-selectable pressure ranges offer the flexibility to precisely match the application’s requirements . The adjustable damping feature is particularly beneficial in this environment, as it smooths the output signal, preventing erratic readings from air turbulence caused by doors opening and closing, thus ensuring a stable input to the monitoring system.

The cornerstone of the system is the MultiCon CMC-N16, a powerful multichannel controller and data logger . Acting as a Modbus Master, the CMC-N16 communicates over a single RS-485 network to poll and aggregate data from all the ProSens and DPS 300 transmitters installed across the facility . With its large internal memory and advanced data logging capabilities , the CMC-N16 provides a complete, compliant, and centralized record of all critical environmental parameters. This is essential for the facility’s quality assurance processes and regulatory audits. The device’s colour display allows for rich local data visualization in various formats like trends and charts , while its Ethernet port enables facility managers to connect to a PC for remote monitoring and configuration .

ProSens Climate Monitor & Controller

- Part No: QM-211-00-0-3-1-22-1-10-3-4

- Type of probe: integrated radial, length 40 mm, Ø 18 mm, stainless steel 316L, PTFE filter cap

- Measurement 1: temperature & humidity probe (3)

- Measuring temperature range: -30 ÷ 80°C

- Measuring humidity range: 0 ÷ 100% RH

- Measurement 2: universal input (I, U, RTD, TC) (1)

- Output: 2 x AO (0/4-20 mA, active, non-isolated) (22)

- Display: LCD, 128 x 64 pixels (1)

- Communication interface: RS-485 / Modbus RTU (10)

- Power supply: 24V DC (3)

- Case: Wall mounted

- Protection Class: IP65

- The number of available glands: 4 pcs (4)

DPS 300 Differential Room Pressure Sensor

- Part No: 815-0016-3Z-0-G-C-N-Y00-M-000

- Capsule pressure range: 1.6mbar differential

- Factory set pressure range: 0 – 1mbar (100 Pa) differential

- Proof Pressure: 20,000pa

- Output Signal & Supply Type: 0-20mA or 0-10V / 3 wire selectable

- Output Options: Linear

- Switch Contacts: None

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M16 x 1.5 cable gland

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Air

- Optional Extras: integral LCD readout

CMC-N16 Wall Mounted Multichannel Data Logger

- Part No: CMC-N16-PS42-ETE-E-E-FUN2-0B1

- Slot P – Power Supply 85 – 260V AC/DC, 24V sensor supply output (PS42)

- Block D: Ethernet wired via gland to RJ45 built-in connector (ETE)

- Block C: Empty (E)

- Block B: Empty (E)

- Block A: 2 x Universal Input, isolated (FUN2)

- Extra Options Front USB Host (IP65)

- As standard: Digital inputs 1 x 24V DC, optocoupled;

- As standard: Communication interface: RS-485/Modbus RTU,

- As standard: USB device (service)