Easily log and analyze pressure data on your PC. These digital sensors connect via serial interfaces and come with software for preset interval logging of fluids and gases.

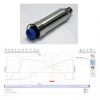

This range of digital pressure sensors are specifically designed for straightforward connection to desktop or laptop computers, enabling sophisticated data logging capabilities for both air and liquid pressures. Featuring versatile serial bus interface options such as USB, RS485, and RS232, these sensors, when paired with the supplied data logging software, allow engineers and technicians to configure preset logging intervals, monitor real-time data, and analyze pressure trends for a wide array of research, industrial process control, and testing applications.

1000 psi USB connection pressure transducer for PC data acquisition - Pressure transducer with USB connection and PC software for data acquisition of pressures from 0 to 1000 psi gauge.

1000 psi USB connection pressure transducer for PC data acquisition - Pressure transducer with USB connection and PC software for data acquisition of pressures from 0 to 1000 psi gauge.

UPS-HSR USB Pressure Sensor with High Sample Rate Logging

UPS-HSR USB Pressure Sensor with High Sample Rate Logging 33X High Accuracy Digital Output Pressure Sensor

33X High Accuracy Digital Output Pressure Sensor 41X Low Range Digital Output Pressure Sensor

41X Low Range Digital Output Pressure Sensor 35X Flush Diaphragm Digital Output Pressure Sensor

35X Flush Diaphragm Digital Output Pressure Sensor

Find out more about Pressure Sensors for Data Logging with a Computer to determine which product options and capabilities will best meet your application requirements.

Digital pressure sensors designed for direct integration with computer-based data logging systems offer a streamlined solution for engineers and technicians needing to monitor, record, and analyze air and liquid pressure fluctuations. These sensors typically feature a direct digital output, eliminating the need for external analog-to-digital converters and preserving signal integrity from the point of measurement to the computer. The ability to connect via common serial bus interfaces, such as USB, RS485, or RS232, provides versatile interfacing options suitable for various environments, from laboratory benchtops to industrial installations.

USB connectivity offers plug-and-play convenience, often drawing power directly from the computer, making it ideal for portable measurement setups or applications where simplicity is paramount. For more demanding industrial environments or applications requiring longer transmission distances and higher noise immunity, RS485 interfaces are frequently employed. RS485 also supports multi-drop configurations, allowing multiple sensors to be connected on a single bus, which is beneficial for monitoring various points in a complex system. RS232, a more traditional serial interface, remains a reliable option for direct point-to-point communication with legacy systems or specific industrial controllers.

A critical component of these systems is the accompanying data logging software, which is installed on a desktop or laptop computer. This software transforms the PC into a sophisticated pressure monitoring and recording instrument. Users can typically configure parameters such as the logging interval, defining how frequently pressure readings are captured – from rapid sampling for dynamic events to slower rates for long-term trend analysis. Advanced software packages may also offer features like real-time graphical displays, data export in various formats (e.g., CSV, Excel) for further analysis, alarm configurations for out-of-tolerance conditions, and sensor calibration utilities.

These pressure sensing systems are invaluable in a range of applications. In research and development labs, they can be used for material testing, aerodynamic studies, or bioreactor pressure monitoring. Process engineers might deploy them for tracking hydraulic or pneumatic system performance, monitoring vessel pressures in chemical processing, or verifying line pressures in manufacturing facilities. Instrument technicians can utilize them for diagnostics, leak detection, and system calibration tasks. The ability to log both air and liquid pressures, combined with selectable logging intervals, makes these sensor systems adaptable for tasks such as environmental pressure monitoring, HVAC system analysis, or performance testing of components on test benches. Careful consideration of sensor material compatibility with the specific fluids or gases being measured is crucial for ensuring long-term accuracy and sensor longevity.