A customer developing control systems for climate rooms required a solution for maintaining precise environmental conditions. The primary challenge was to not only manage very low bidirectional differential air pressure but also to integrate temperature and relative humidity measurements into a single, cost-effective control package. The final solution successfully combined a specialised low-range differential pressure transmitter with a versatile, multi-function environmental controller. This created a compact, standalone system capable of monitoring all parameters and directly controlling HVAC equipment via built-in relays.

- Application: Bidirectional pressure, temperature, and relative humidity control for climate rooms.

- Challenge: Integrating multiple sensor signals for pressure, temperature, and humidity into a cohesive and affordable control solution.

- Solution: A low-range differential pressure transmitter was paired with a universal input environmental controller featuring an integrated temperature and humidity probe.

- Benefit: This provided a single, all-in-one unit for local display, multi-parameter measurement, and direct control, significantly reducing system complexity, wiring, and overall cost.

A control systems integrator required instrumentation for maintaining tightly controlled atmospheric conditions within climate rooms. The core of the application involved managing very low-level air pressure, ensuring it remained within a precise bidirectional differential range of -150 to +150 Pascals relative to the surrounding environment. This level of control is critical in specialised environments, such as research labs or sensitive manufacturing areas, to prevent contamination and maintain process stability by controlling both over-pressure and under-pressure conditions.

Initial discussions focused on specifying a suitable low-range differential pressure transmitter. However, it became apparent that the customer also needed to monitor and control the temperature and relative humidity within the same space. The challenge then evolved from sourcing a single sensor to designing a complete, yet economical, multi-parameter control system. Proposing separate sensors for pressure, temperature, and humidity, along with a separate programmable controller, would have increased component costs, wiring complexity, and the overall physical footprint of the installation.

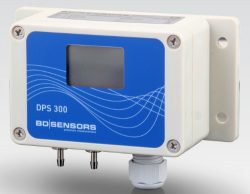

The proposed solution elegantly addressed all requirements by pairing two complementary devices: a DPS300 series differential pressure transmitter and a ProSens series environmental monitoring and control device.

The DPS300 was selected to handle the critical low-pressure measurement. Optimised for HVAC applications, it provides the required ±1.5 mbar range with an accuracy of 1% full scale, making it ideal for detecting the subtle pressure fluctuations in the climate room. Its design for use with dry, non-aggressive gases was perfectly suited to the clean air environment. To ensure the highest accuracy at these low pressures, installation best practices were followed, such as mounting the device vertically with the pressure ports facing downwards to prevent any potential for condensation to gather in the tubing and affect the reading.

The heart of the solution is the ProSens controller, which acts as an integrated hub for measurement, display, and control. This device was configured with an integral temperature and relative humidity probe, immediately solving two of the measurement needs in one unit. Crucially, it was also equipped with a universal input capable of accepting the 4-20mA signal from the external DPS300 pressure transmitter. This allowed all three critical parameters, pressure, temperature, and RH, to be consolidated into a single device.

The key advantage of this combined solution was the ProSens device’s built-in control functionality. Equipped with two electronic relays, it could function as a complete, standalone controller for the climate room’s HVAC system. The user could program setpoints and hysteresis directly through the device’s menu for all three measurement channels. For example, the relays could be configured to activate an exhaust fan if a specific over-pressure threshold was exceeded, or trigger a humidifier if the relative humidity dropped below a certain point.

This approach provided a feature-rich solution in a compact, wall-mounted enclosure. A large, backlit LCD on the ProSens unit gives maintenance staff a clear, at-a-glance reading of all live parameters and the status of the control relays, simplifying commissioning and troubleshooting. While operating as a standalone system, the inclusion of an RS-485 Modbus RTU interface offers the flexibility to integrate the climate room into a larger building management system (BMS) for centralised monitoring and data logging in the future.

ProSens Climate Monitor

- Part No: QM-212-00-0-3-1-11-1-10-3-3

- Probe Version: Radial, Ø18mm, L=90mm

- Connector & Cable Type: None (when Radial probe supplied)

- Cable Length: None (when Radial probe supplied)

- Measurement 1: Temperature & Humidity Probe (supplied & installed)

- Measurement 2: Universal input (I, U, RTD, TC)

- Output Option: 2 electronic NO relays, 24V AC/35V DC, max. 200 mA

- Display: 2.9″ LCD, 128 x 64 pixels with backlight

- Number of Cable Glands: 3pcs

- Power Supply: 24V DC (11 ÷ 36V DC), power consumption: 2.5 W max

- Communications Interface: RS-485, 8N1 and 8N2, 1200 bit/s ÷ 115200 bit/s, Modbus RTU, not galvanically isolated

- Operating temperature range: -30°C ÷ +80°C, case with electronics (out of range -20 ÷ +70°C LCD and IR receiver turn off)

- IP Protection Class: IP 67 (version without display); IP 65 (version with display)

- Case: Wall mounted, 120 x 90 x 50 mm, ASA LURAN

DPS 300 Bi-Directional Differential Room Pressure Sensor

- Part No: 815-S1K5-1-0-G-0-N-Y00-M-000

- Capsule pressure range: 1.6mbar diferential

- Factory set pressure range: -1.5… +1.5 mbar differential

- Proof Pressure: 20,000pa

- Output Signal: 4-20mA, 2-wire

- Supply voltage: 11… 32 VDC

- Output Options: Linear

- Switch Contacts: None

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M16 x 1.5 cable gland

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Air

- Optional Extras: None