Measuring the liquid level of concentrated ammonium nitrate in industrial storage presents a multi-faceted challenge involving high fluid density, elevated temperatures, and the risk of mechanical clogging. In this specific use case, a 6000-liter agitated tank requires a level monitoring solution that can provide high-accuracy hydrostatic data while resisting the corrosive nature of the media and the turbulence caused by internal mixing.

- Low-Pressure Sensitivity: The ability to accurately measure a liquid column of only 200 mm, which exerts a hydrostatic pressure of approximately 16 to 20 mbar.

- Thermal Resilience: Capability to operate continuously with media temperatures at 80°C, specifically where the medium is at its boiling point.

- Chemical Compatibility: Wetted materials must resist ethanol and water mixtures at high temperatures without leaching or seal failure.

- High Precision: A desired accuracy of a “couple of millimeters,” requiring a total error band of less than 1% of the full scale.

- System Integration: A standard industrial output signal compatible with a 2-wire current loop for conversion to a voltage signal for microcontrollers.

The primary difficulty in monitoring ammonium nitrate solutions at a process temperature of 80°C lies in the physical and chemical characteristics of the media. At these concentrations, the solution is significantly denser than water, requiring a precise understanding of specific gravity to calibrate hydrostatic pressure readings into linear level measurements. For a tank height of 220 cm, the resulting pressure at the base is higher than standard water-based calculations, necessitating a sensor calibrated for a broader pressure range to provide sufficient headroom and prevent over-pressure scenarios during high-fill cycles. Furthermore, the presence of an agitator introduces localized pressure fluctuations and mechanical turbulence that can wear down standard metal diaphragms or lead to unstable readings if the sensor technology is not sufficiently robust.

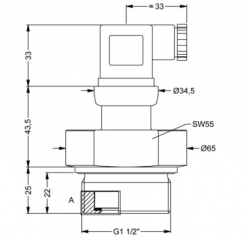

To address the risk of media buildup and crystallization, a flush-mounted mechanical interface is essential. Standard pressure ports with internal cavities are prone to “plugging,” where the ammonium nitrate solution stagnates, cools, and eventually crystallizes, effectively isolating the sensing element from the process pressure. By utilizing a G1 1/2 inch male thread with a flush diaphragm, the sensing surface sits perfectly level with the internal tank wall. This configuration ensures that the constant motion of the agitated fluid provides a self-cleaning effect across the face of the sensor, preventing the accumulation of solids and ensuring a continuous, unobstructed pressure path.

The selection of a capacitive ceramic sensor provides a distinct advantage over traditional piezoresistive metal-foil technologies in this application. The high-purity ceramic sensing element is a “dry” cell, meaning it does not rely on internal oil-filled capillaries to transfer pressure from a thin metal diaphragm to the internal bridge. This eliminates the risk of process contamination should a diaphragm breach occur and provides exceptional resistance to the corrosive attack of hot ammonium nitrate. Ceramic is also far harder and more abrasion-resistant than stainless steel, allowing it to withstand the constant impact of turbulent, high-density fluids and any suspended particulates without deforming or losing calibration accuracy over time.

For safety and integration into industrial control loops, the instrumentation must adhere to intrinsically safe standards, as ammonium nitrate handling areas are often classified as hazardous. A loop-powered 4-20mA output allows for simple integration into existing PLC or SCADA systems, while the use of a high-performance fluoroelastomer seal ensures that the internal housing remains protected from chemical ingress at the connection point. This combination of inert material selection and robust mechanical design allows for a maintenance-free installation that provides reliable, real-time level data in one of the more demanding chemical processing environments.

The LMK 351 series serves as a specialized hydrostatic level solution, specifically engineered to withstand the demanding conditions of chemical storage involving agitated and corrosive media.

LMK 351 Screw-In Flush Hydrostatic Level Transmitter

- Part Number: 470-4000-E-3-100-M00-1-1-C-000

- Measuring Range: 0 to 400 mbar gauge

- Output Signal: 4-20mA, 2-wire, Intrinsically Safe (ATEX/IECEx)

- Accuracy: 0.35% FSO

- Electrical Connection: DIN 43650 plug and socket (IP65)

- Mechanical Connection: G1 1/2 inch male DIN 3852 flush diaphragm

- Diaphragm Material: Ceramic Alumina Al2O3 99.9%

- Housing Material: Stainless Steel 316L

- Internal Seals: FKM (Viton)

- Media Operating Temperature Range: -40 to +125 degrees Celsius