This application required a dependable method to monitor fluctuating seawater levels in the tidal river to protect submersible abstraction pumps from damage caused by low water conditions. Following a detailed evaluation of the application’s challenges, including corrosion, secure mounting in a river current, and potential silt accumulation, a screw-in hydrostatic level transmitter was chosen. The final solution successfully addressed the need for a robust, accurate sensor capable of providing a continuous level signal for pump control while withstanding the harsh marine environment.

- Primary Goal: To provide a continuous 4-20mA level signal for controlling submersible pumps and preventing damage from running dry in a tidal seawater environment.

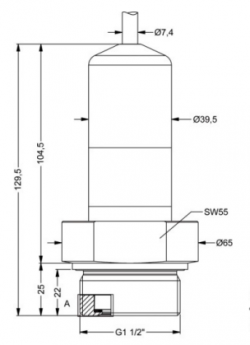

- Sensor Selection: The LMK458 series Marine Approved Hydrostatic Level Transmitter was specified with a G1 1/2 male screw-in process connection, chosen over a probe version to ensure a secure, fixed mounting on a submerged bracket.

- Seawater Compatibility: A key feature was the sensor’s Copper-Nickel-Alloy (CuNiFe) housing, selected specifically for its corrosion resistance and long-term reliability in seawater applications.

- Diaphragm Care: The screw-in version features a flush ceramic diaphragm. While this design helps reduce clogging from residues, the diaphragm is highly vulnerable to mechanical damage during handling and installation, necessitating careful procedures to avoid impact.

- Vented Cable Installation: The sensor uses a vented cable to provide an accurate atmospheric pressure reference. It was critical to terminate the cable’s open end inside a dry, outdoor-mounted enclosure to protect the delicate vent filter from moisture ingress, which could block the reference and cause measurement errors.

A design team for a renewable energy water source heat pump for district heating was tasked with implementing a reliable level monitoring system for abstraction pumps in a tidal river, a challenging seawater environment. The primary objective was to protect the submersible pumps by ensuring they would not operate below a critical minimum water level, thus preventing potential damage. The installation involved positioning the pump’s inlet filter 300mm from the riverbed’s highest point, with the pump’s minimum operational level set 700mm above this filter. The level sensing solution needed to accurately track tidal variations, with high tides reaching approximately 4 meters above the critical pump operating level, and provide a continuous signal for pump control. The system also required an integrated temperature measurement capability. After initial considerations of a probe-style sensor, the decision was made to utilize a screw-in version of the level transmitter, providing a more secure and fixed mounting method for this demanding application.

The specific challenges of this tidal seawater application included selecting a sensor with appropriate material compatibility to resist corrosion and addressing potential issues like silt accumulation affecting the exposed diaphragm. The chosen G1 1/2 male screw-in mounting needed to be integrated into the submerged infrastructure, likely onto a custom plate or bracket, ensuring stability against river currents and potential debris. Protecting the sensor’s delicate ceramic diaphragm, especially for a low measurement range of 0 to 5 meters of water, remained a key consideration during handling and installation, as the screw-in version presents a flush diaphragm without a protective nose cone. Ensuring the integrity of the vented cable system, crucial for accurate gauge pressure measurement, was also paramount, with the cable termination planned for an outdoor-mounted stainless steel enclosure requiring careful protection of the vent tube’s filter from moisture ingress.

The proposed solution centered on the LMK458 series Marine Approved Hydrostatic Level Transmitter, specifically the G1 1/2 male screw-on variant. This sensor was selected for its robust Copper-Nickel-Alloy (CuNi10Fe1Mn) housing, ideal for prolonged seawater immersion, and its high-purity ceramic Al2O3 96% diaphragm. The 0 to 5 mH2O pressure range with a 0.25% Full Scale accuracy and a 4-20mA output signal met the requirement for precise and continuous level monitoring. An optional integrated PT100 temperature sensor was included. It was decided that the screw-on version, intended for tank fitting, would be suitable for liquid media, and that its flush design will be advantageous with thicker fluids such as silt, that will lead to residues in crevices of nosed probes.

Key advantages of the screw-on LMK458 included its secure threaded mounting, offering a fixed and stable installation. While the screw-on design does not feature a detachable nose cone, its flush diaphragm is less prone to specific types of clogging in crevices compared to probe designs with protective caps, though care during installation is vital to prevent mechanical damage. This is due to the vulnerability of the diaphragm to point loads and the need for careful handling.

To mitigate interference, it was advised to isolate the sensor from direct pump vibration and potential electromagnetic interference as much as the mounting allows. The LMK458 series utilizes a vented cable for atmospheric reference. Detailed guidance was provided on terminating this cable within a dry, ventilated enclosure, ensuring the vent tube’s integrated filter was protected from moisture. The TPE-U cable offered durability for submersible use. While the sensor could theoretically transmit pressure through wet silt, heavy clogging of the exposed diaphragm could impede performance, a factor for long-term reliability.

LMK458 Screw-On Seawater Resistant Flush Diaphragm Hydrostatic Level Transmitter

- SKU ID: s1-lmk458-0035

- Part No: 766-5000-K-5-C-1-1-4-2-030-013

- Pressure Range: 0 to 5 mH2O

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: G1 1/2 male screw-in version

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 99.9%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 30

- Cable Length Units: Metres (m)

- Optional Extras: PT100 integral temperature sensor