Analogue output sensor for immersing in seawater to determine depth or change in water level by measuring hydrostatic pressure.

This sea depth probe has a Marine bronze housing and Ceramic diaphragm for protection from saltwater corrosion.

Select fixed ranges from 10 metres (33 feet) up to 100 metres (328 feet) depth in a number of analogue output configurations including low voltage strain gauge, amplified voltage and current loop output.

Also suitable for use in brackish and inland tidal water or any other application where there is the risk of corrosion form a saline liquid.

Product Parameters

- Hydrostatic Level Ranges: 0-10 mH2O (33 ftH2O) up to 0-100 mH2O (328 ftH2O), 0-1.5 bar (15 psi) up to 0-10 bar (150 psi) absolute

- Accuracy: 0.25% or 0.1% full scale BSL (11-12 bit resolution)

- Output Signal: 4 to 20 mA current loop output and amplified voltage, mV/V uncompensated, 2mV/V ±1% rationalised, 10 mV/V ±1% rationalised and low amplification

- Electrical Connection: IP68 sealed with PUR, FEP or TPE coated cable.

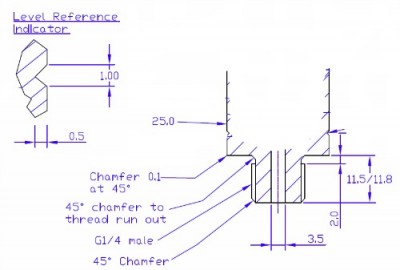

- Pressure Connection: 1/4 BSP male with protective nose cone

- Media Compatibility: Marine bronze CA104 body, Ceramic Alumina Al2O3 diaphragm with NBR, Viton or EPDM O ring seals, PUR, FEP or TPE cable jacket

- Diameter: 25 mm (1 inch)

- Special Features: salt water compatible marine bronze housing and ceramic diaphragm

- Special Options: TPE cable for improved protection from long term exposure to seawater

Product Description

The SWL is specially designed for protection against corrosion in salt water. The body of this submersible seawater level sensor is made from Aluminium Bronze which is a copper alloy with a 10% Aluminium composition and a smaller percentage of Manganese, Nickel and Iron. Aluminium Bronze is a proven long lasting material used extensively by the marine industry to manufacture components which will be permanently immersed in seawater.

For added protection on permanent installations a TPE coated cable can be specified for the electrical connection which is highly resistant to damage from long term exposure to seawater.

The SWL IP68 saltwater depth sensor has many different types of analogue output signal to match any application including a 4-20mA current loop signal for installations on ships or offshore platforms, or a mV/V strain gauge output for low battery consumption on isolated environmental monitoring instrumentation at sea or around coastal waters.

Product Applications

Marina tide level

Use in a marina to measure tide level, with 24vdc loop power input and 4-20ma output, and made from materials which are suitable for use in sea water.

- SKU ID: s1-swl-0002

- Part No: SWL-G1000-5A4-BAV-011-000

- Pressure Range: 10

- Units: mH2O

- Range Type: Gauge / Vented (atm to +P)

- Output Signal: 4-20mA (2wire)

- Non-Linearity and Hysteresis: 0.25% FS

- Thermal Zero Shift: 0.04% FS/deg °C

- Cable Type: TPE

- Cable Length: 11

- Cable Length Units: Metres (m)

- Housing Material: Marine bronze CA104

- Diaphragm Material: Ceramic Alumina (Al2O3)

- Media Exposed Seals: Viton

- Process Connection: G1/4 male DIN3852 with removable nose cone

Product Help

Seawater lock

I am looking for a hydro static sensor to put in a seawater lock to measure a maximum depth of 9 meters and send out a 4 – 20mA signal?

We would suggest a 10 meter range SWL with a 4-20mA output which compatible with seawater as standard.

- SKU ID: s1-swl-0003

- Part No: SWL-G1000-5A4-AAV-020-000

- Pressure Range: 10

- Units: mH2O

- Range Type: Gauge / Vented (atm to +P)

- Output Signal: 4-20mA (2wire)

- Non-Linearity and Hysteresis: 0.25% FS

- Thermal Zero Shift: 0.04% FS/deg °C

- Cable Type: PUR

- Cable Length: 20

- Cable Length Units: Metres (m)

- Housing Material: Marine bronze CA104

- Diaphragm Material: Ceramic Alumina (Al2O3)

- Media Exposed Seals: Viton

- Process Connection: G1/4 male DIN3852 with removable nose cone

3000 air pressure in 50m deep underwater pipe

I need submersible pressure sensor that can be used in marine environment for my research project. I have an underwater pressure vessel which contains pressurized air. The pressure inside the pressure vessel is about 3000 psi. The vessel will be used at a 50 m depth below the water surface. Can the SWL be used as an underwater pressure sensor to sense air pressure inside a pressure vessel?

The SWL can be submerged to a depth of up to 100 metres and if connected to a underwater pipe it is possible to offer higher pressure ranges such as 3000 psi.

- SKU ID: s1-swl-0001

- Part No: SWL-AP3K0-5A4-BAV-060-000

- Pressure Range: 3000

- Units: psi

- Range Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4-20mA (2wire)

- Non-Linearity and Hysteresis: 0.25% FS

- Thermal Zero Shift: 0.04% FS/deg °C

- Cable Type: TPE

- Cable Length: 60

- Cable Length Units: Metres (m)

- Housing Material: Marine bronze CA104

- Diaphragm Material: Ceramic Alumina (Al2O3)

- Media Exposed Seals: Viton

- Process Connection: G1/4 male DIN3852 with removable nose cone

20 bar range in mounting on underwater pipe

If the SWL was in shallow water and fitted to an underwater pipe to measure pressure, would it be okay to measure up to 20 bar with very low external pressure?

Yes that is okay, non-standard ranges up to 200 bar have been supplied previously.

Measure pressure inside submerged vessel compared to depth

We want to measure the difference in pressure between the inside and outside of a submersible vessel. The vessel will be submerged in seawater to a depth of 35 metres and pressurised up to 10 bar with Nitrogen gas. What do you suggest for monitoring the pressure difference?

We would suggest using two separate SWL sensors, one for measuring depth and the other screwed into the vessel to measure the nitrogen gas pressure. The SWL is seawater compatible and waterproof to the required depth.

Benefit of TPE cable jacket

What are the benefits of using the TPE coated cable instead of PUR on the SWL marine bronze submersible level sensor?

The TPE (Thermoplastic elastomer) signal cable has a ruggedised outer sheath for improved abrasion resistance, and the rubber compound has been specially developed for long term resistance to sea water.

Offshore approval

I need to recover the draft measurement system measurement of some semi submersible units. The original system used to work with a bubbler. I would like to know if the SWL Marine Bronze Submersible Level Sensor product has already been applied in some offshore oil platform, which is approved by classification society (ABS, BV, DNV, GL, Lloyds, NKK, etc…?

The SWL has not been submitted for offshore approval, and therefore we would recommend the LMK458 as an alternative, since it has been used successfully in offshore applications such as offshore oil platforms and ships, and is DNV & GL approved to comply with shipping and offshore standards.

Absolute or gauge reference

I need to use a 5 bar pressure range to measure seawater depth of an underwater measurement device, do I need to specify a gauge or absolute pressure range?

You could use either, but it depends on where you are terminating the cagble. If the sensor pressure range is 0 to 5 bar absolute, the depth 30mH2O, and the barometric pressure happens is 950 mbar, the sensor will measure 0.95 + 30mH2O total pressure. So to determine the true depth you would need to subtract barometric pressure.

Alternatively a 0 to 5 bar gauge range would have a vent included in the cable which you would either terminate inside the housing at atmospheric pressure or run to a connection on the surface. If the vent is connected to surface air pressure this will be the best way to compensate for atmospheric pressure. If the vent is connected to the inside of the submerged vessel for a short period of time, the surface air pressure will still be similar to pressure inside of the vessel. So the sensor would cancel out the atmospheric effect on depth pressure, and therefore you would not need to subtract the atmospheric pressure. However if the vessel is submerged for long periods, the air pressure inside the housing will be isolated from atmospheric pressure and therefore there will be discrepancy in compensation.

Gauge pressure – vented to surface atmospheric pressure

This is the preferred installation for the best accuracy, but not always convenient with submersibles.

Gauge pressure – vented to vessel internal air pressure

This would be okay for short time periods, but compensation will become less accurate as surface atmospheric & internal vessel pressure change independently.

Absolute pressure – non-vented

This would require separate atmospheric pressure reading to compensate for true depth.

Mounting hole thread size

Our workshop needs to make a hole to mount the sensor, could you explain the type of thread used on the SWL and provide the distance between the threads ?

The thread underneath the removable nose cone is G1/4 male also known as 1/4 BSP P male, which has thread pitch of 1.337mm or 19 TPI (threads per inch).

How to remove nose cone

We just received the pressure sensor, but how do you remove the nose cone since we want to use it inside a device to measure outside pressure, we tried removing by hand but it was not possible?

You can place a screw driver, or any metal bar with a similar diameter, through the hole on the end of the nose cone for extra leverage to unscrew it.

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the SWL Marine Bronze Submersible Level Sensor in your application and request a quote.

"*" indicates required fields