An engineering contractor was tasked with modernizing the tank level gauging system on a ship by replacing an outdated bubbler system. The primary challenges were sourcing a sensor with a diameter small enough to fit inside existing 25mm guide pipes and ensuring the solution was certified as intrinsically safe for use in diesel fuel tanks. A slim, marine-approved hydrostatic level probe provided a direct and effective solution.

- Application: Ship tank level measurement retrofit

- Challenge: Sensor must fit 25mm ID pipe

- Media: Diesel fuel

- Requirement: ATEX intrinsic safety certification & marine approval

- Solution: LMK 487 hydrostatic level probe

An automation and systems engineering contractor was commissioned to undertake a significant instrumentation upgrade on a marine vessel. The project required the replacement of approximately 30 existing level sensors across various tanks used for diesel fuel. The ship’s original system was a ‘bubbler’ type, where pressure sensors were mounted at the top of pipes leading into each tank. The goal was to modernize this setup with a more direct and reliable measurement method, specifying a 4-20mA, 2-wire output for straightforward integration into the vessel’s updated control systems.

A significant technical constraint quickly became apparent: the existing guide pipes into the tanks had a narrow internal diameter of only 25 mm. This meant that any replacement sensor had to be slim enough to be lowered directly into these pipes without requiring expensive and disruptive mechanical modifications to the tanks. Furthermore, for the sensors destined for diesel fuel tanks, an intrinsically safe (Ex ia) design was a mandatory safety requirement. This certification ensures that the sensor’s electrical and thermal energy is too low to cause ignition in a potentially explosive atmosphere, a critical consideration when dealing with hydrocarbon fuels. The required measurement range was specified as 0 to 10 metres of water gauge.

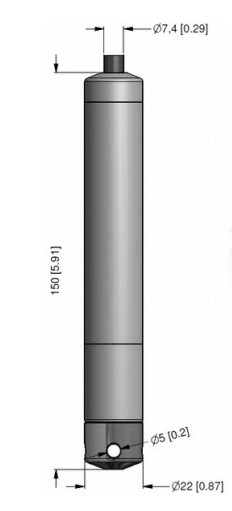

The LMK 487 series hydrostatic probe was identified as the ideal solution to meet these demanding requirements. Its most crucial feature for this retrofit application was its slim 22 mm external diameter , which allowed it to be easily installed inside the customer’s existing 25 mm pipes. This eliminated the need for any physical alterations to the ship’s tank infrastructure, saving significant time and cost. Specifically developed for marine and offshore use , the LMK 487 is type-approved by Lloyd’s Register (LR) and DNV GL , assuring its suitability and reliability for critical shipboard applications like monitoring levels in fuel storage tanks. The selected version featured an ATEX intrinsically safe certification (Ex ia) , making it fully compliant for use in the diesel fuel tanks where a Zone 0 hazardous environment could exist.

Material compatibility and long-term stability were also key factors. The sensor’s diaphragm is constructed from high-purity (99.9%) aluminium oxide ceramic , which provides excellent resistance to the corrosive effects of seawater and the chemical properties of diesel fuel, while also ensuring high long-term measurement stability. The media-exposed seals were specified as FKM, a material known for its excellent compatibility with hydrocarbons and fuels. This robust construction, combined with a 316L stainless steel housing, ensures the sensor can withstand the harsh conditions of a marine environment. The standard range of 0 to 10 mH₂O was readily available with a high accuracy of 0.25% of full scale, providing the precise tank gauging data required by the vessel’s crew.

LMK487 Marine Approved 22mm dia Submersible Fuel Level Probe

- Part No: 366-6000-1-1-C-E-1-4-2-010-000

- Pressure Range: 0 – 6mWG

- Output Signal: 4 to 20mA, 2 wire Intrinsically Safe

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Stainless steel 1.4404 (316L)

- Diaphragm Material: Ceramic Al2O3 99.9%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 10

- Optional Extras: ATEX Approved Ex ia