Methyl Ethyl Ketone solvent compatible pressure transmitter with a 0-5V dc analogue output for measuring pressures from 0 to 5 bar gauge.

MEK Solvent Compatible Pressure Transmitter

- Part No: IMP-G5000-6A4-BAE-00-000

- Pressure Datum: Gauge

- Pressure Range: 0 – 5 Bar

- Output: 0 – 5V / 3-wire

- Accuracy (Combined NL&H): <±0.25% / FS

- Accuracy (Thermal Zero Shift): <±0.04% / FS / °C

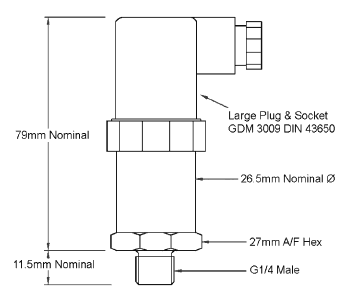

- Electrical Connection: Large Plug & Socket (GDM3009, DIN43650)

- Process Connection: G 1/4″ male DIN 3852

- O Ring Material: EPDM

- Cable Length (Metres): No Cable

- Specials Code: No Special Requirements

- Diaphragm Material: Aluminium Oxide 96% (Ceramic Al2O3)

- Process Connection Material: 303 Stainless Steel

- Media Temperature: -20 to +135°C

- Operating Temperature: -20 to +80°C

- Supply Voltage: 9 – 32V dc