This solution provides a robust, industrial-grade level measurement for low-height boilers and laboratory containers. By combining high-purity ceramic sensing technology with chemically resistant elastomers, it ensures long-term stability in aggressive, high-temperature environments.

- Capacitive Ceramic Technology: High sensitivity for extremely low hydrostatic pressures.

- High-Temperature Rating: Operates reliably in media up to 125°C (with stainless steel port).

- Chemical Resistance: EPDM seals and alumina diaphragms are ideal for ethanol and alcohol-based mixtures.

- Flush Mount Design: Eliminates media build-up and ensures accurate readings in small vessels.

This application story examines the challenges of monitoring liquid levels in a small-scale distillation or boiling process involving ethanol and water. In such research environments, precise control is vital for maintaining the thermal balance of the process and ensuring consistent vapor production. The primary technical challenge lies in the combination of very low hydrostatic head pressures—typically less than 20 mbar for a 200 mm column—and the chemical aggressiveness of alcohols at elevated temperatures.

The required measurement solution must provide high sensitivity to detect millimeter-level changes in fluid height while maintaining structural integrity at temperatures reaching 80°C. Standard pressure sensors often fail in these conditions due to the degradation of seals or the thermal instability of the sensing element. Furthermore, the integration with microcontroller-based control systems, such as an Arduino, necessitates a reliable and easily convertible analog output signal to facilitate real-time process adjustments.

- Low-Pressure Sensitivity: The ability to accurately measure a liquid column of only 200 mm, which exerts a hydrostatic pressure of approximately 16 to 20 mbar.

- Thermal Resilience: Capability to operate continuously with media temperatures at 80°C, specifically where the medium is at its boiling point.

- Chemical Compatibility: Wetted materials must resist ethanol and water mixtures at high temperatures without leaching or seal failure.

- High Precision: A desired accuracy of a “couple of millimeters,” requiring a total error band of less than 1% of the full scale.

- System Integration: A standard industrial output signal compatible with a 2-wire current loop for conversion to a voltage signal for microcontrollers.

The recommended solution is the LMK 351 series screw-in transmitter, which is specifically engineered for measuring small system pressures and container levels. This transmitter utilizes an own-developed capacitive ceramic sensor element, providing the high sensitivity required for low-pressure ranges down to 40 mbar.

- Robust Material Configuration: To handle the ethanol-water mixture at 80°C, the solution features a 316L stainless steel pressure port. While PVDF options exist, the stainless steel housing is essential for this application as it maintains performance up to 125°C, whereas plastic variants are often limited to 60°C.

- Advanced Sealing: The sensor is configured with EPDM (Ethylene Propylene) seals. This material provides excellent chemical resistance to alcohols, ensuring the internal electronics remain protected from the boiling medium.

- Millimeter-Level Accuracy: With a standard accuracy of 0.35% FSO (Full Scale Output), the transmitter provides a precision of approximately 1.4 mm over a 40 mbar range, exceeding the customer’s requirement for “millimeter-level” control.

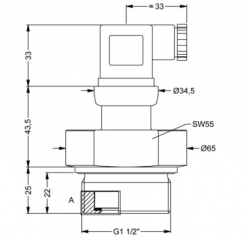

- Flush Diaphragm Design: The G 1 1/2″ flush-mounted sensor prevents air pockets and ensures the high-purity 99.9% Al2O3 ceramic diaphragm is in direct contact with the medium for instantaneous response to level changes.

- Simplified Interfacing: The 4-20 mA 2-wire output allows for easy integration with an Arduino. By utilizing a high-precision resistor, the current signal is converted into a stable voltage signal, enabling precise digital level monitoring.

LMK 351 Screw-In Flush Hydrostatic Level Transmitter

- Part Number: 470-0400-1-3-100-M00-3-1-C-000

- Measuring Range: 0 to 40 mbar (0.04 bar)

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4-20mA, 2-wire

- Accuracy: 0.35% FSO

- Electrical Connection: DIN 43650 plug and socket (IP65)

- Mechanical Connection: G1 1/2 inch male DIN 3852 flush diaphragm

- Diaphragm Material: Ceramic Alumina Al2O3 99.9%

- Housing Material: Stainless Steel 316L

- Internal Seals: FKM (Viton)

- Media Operating Temperature Range: -40 to +125 degrees Celsius