Low range three in one pressure switch, pressure indicator and pressure sensor for use on pneumatics and HVAC applications in a choice of ranges starting from 0 to 10 mbar gauge (4 inH2O) up to 0 to 1000 mbar gauge (400 inH2O) plus a 0 to -1000 mbar vacuum range. Compatible with gases, compressed air and low viscosity non-aggressive fluids.

Product Parameters

- Pressure Ranges: 10 mb up to 1 bar g and -1 bar g

- Accuracy: 0.35%FS > 0.1 bar, 0.5%FS <= 0.1 bar, IEC 60770 (analogue output)

- Output Signals: 4 to 20 mA 2 wire, 0 to 10 Volt 3 wire and Adjustable 4 to 20 mA 3 wire

- Electrical Connections: DIN43650A plug & socket, cable gland, Binder 5 pin, M12 x 1 5-8 pin plastic or 5 pin metal connector

- Pressure Connections: G1/2 and G1/4 DIN 3852 or EN837, G1/2 DIN 3852 open port, 1/2 and 1/4 NPT male

- Display: 4 digit red LED, ±0.1% FS ± 1 digit accuracy plus analogue output accuracy

- Switch Contacts: PNP, 125 mA max for 4-20 mA (2 or 3 wire) and 500 mA max for 0-10 V output.

- Environmental Protection: IP 65

- Special Options: 5 to 1 rangeable, ATEX approved for hazardous areas

Product Description

The DS 210 low pressure switch, indicator and sensor utilises an exposed silicon diaphragm for extra sensitivity at low pressures whilst maintaining a high accuracy for the analogue output of 0.35% full scale for ranges above 100 mbar and 0.5% full scale for ranges below 100 mbar.

The digital LED display can be configured by the user to display in any pressure units and the 1 or 2 switch contacts can be set to trigger at any pressure within the range. The DS230 combined low pressure switch, readout and sensor is externally powered via a cable or connector exiting from the top of the instrument which is also used for the analogue output if specified.

Product Applications

Vacuum blockage detection

Detect whether a vacuum system is blocked or if there is a lack of vacuum power.

- SKU ID: s1-ds210-0001

- Part No: 78A-X102-1-2-3-N01-300-1-000

- Pressure Range: -1000 to 0

- Units: mbar

- Range Type: Negative Gauge/Suction (atm to -P)

- Output Signal: 4-20mA (2 wire)

- Accuracy: 0.35%FS

- Switch Output: 2 PNP switches

- Electrical Connection: M12 x 1, 5 pin plastic connector

- Process Connection: G1/4 DIN3852 male

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: stainless steel 1.4404 (316L), silicon, Epoxy or RTV, glass

- Media Exposed Seals: FKM

Product Help

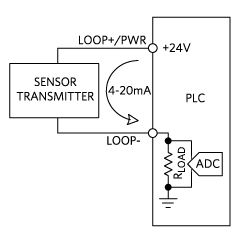

Connecting a 2-wire 4-20ma pressure switch to a PLC

Can a 2-wire 4-20mA pressure switch, such as the DS210, be connected directly to a PLC’s analog input, and what are the power supply and wiring considerations?

Yes, a 2-wire 4-20mA pressure switch is designed for compatibility with PLC analog input cards. These sensors are known as “loop-powered” devices because both the power to operate the sensor and the pressure signal are transmitted through the same pair of wires.

The wiring configuration forms a simple series circuit:

- The positive terminal of an external DC power supply connects to the sensor’s positive (Supply +) terminal.

- The sensor’s negative (Loop -) terminal connects to the PLC’s analog input positive terminal.

- The PLC’s analog input negative terminal connects back to the negative terminal of the power supply, completing the loop.

Power Supply & Load Resistor:

- External Power Supply: You will typically need an external DC power supply, as most PLC analog input cards do not provide loop power. The DS210 series, for example, requires a supply voltage (VS) between 13 and 36 VDC.

- Load Resistor (RL): The PLC’s analog input card has an internal load resistor (typically 250Ω) that converts the 4-20mA current into a voltage (e.g., 1-5 V) for its analog-to-digital converter (ADC). It’s important to ensure the total resistance in the loop does not exceed the sensor’s maximum load capacity, which can be calculated using the formula from the datasheet: Rmax = [(VS − VSmin) / 0.02A].

The above diagram illustrates a standard 2-wire sensor connection. The sensor transmitter is powered by the current loop from the PLC’s power supply.

Adjusting the 4-20ma output span on a pressure switch

Can the 4-20mA analog output on a DS210 pressure switch be re-scaled or have its zero point adjusted after installation to match process conditions?

The ability to adjust the 4-20mA output on the DS210 series depends entirely on the version selected. There is a critical difference between the 2-wire and the 3-wire adjustable models.

- 2-Wire 4-20mA Version: On the standard 2-wire model, the analog output is factory-calibrated and fixed. The zero (4mA) and span (20mA) points cannot be re-scaled or adjusted by the user in the field. While the device menu includes an offset compensation function to correct the local display for mounting orientation effects, this adjustment does not affect the 4-20mA output signal. The 4mA output will always correspond to the zero point of the factory-calibrated pressure range.

- 3-Wire 4-20mA Adjustable Version: This version is specifically designed to provide field adjustability. Using the

ZP(zero point) andEP(end point) menus, you can re-scale the analog output within the sensor’s nominal pressure range. The span can be reduced by a ratio of up to 5:1 (a 20% turn-down).

For example, a 0 to 400 bar unit, factory-set to output 4mA at 0 bar and 20mA at 400 bar, could be reconfigured by the user to output 4mA at 20 bar and 20mA at 300 bar. This is useful for aligning the sensor’s signal with the specific pressure range of a particular process or application.

Calculating the power consumption of a 2-wire 4-20ma sensor

How is the power consumption calculated for a 2-wire 4-20mA sensor, and is it a fixed value?

The power consumption of a 2-wire, loop-powered sensor is not fixed; it varies directly with the measured pressure. This is because the sensor’s operating current is also its signal current, which ranges from 4mA at the lowest pressure to 20mA at the highest pressure of its measurement range.

The power consumption can be calculated at any point in the range using the standard electrical power formula: Power (P) = Voltage (V) × Current (I).

Using a typical 24 VDC loop power supply as an example:

- At zero pressure (4mA signal):

P = 24V × 0.004A = 0.096W - At full-scale pressure (20mA signal):

P = 24V × 0.020A = 0.48W

Therefore, the device’s power draw will fluctuate between these two values as the process pressure changes. This contrasts with 3-wire or 4-wire sensors, where the power for the sensor electronics is supplied on separate wires from the signal output. For those devices, the power consumption is generally stable and constant, as noted in the DS210 datasheet, where the 3-wire versions have a current consumption of approximately 45 mA plus the signal current.

Correcting display offset due to mounting orientation

After installing my low-pressure switch, the display shows a small pressure reading even when there is no pressure applied. How can I correct this display offset?

A minor display offset at zero pressure is a common phenomenon, particularly with sensitive, low-range pressure instruments. It is often caused by the mounting orientation; if the device is installed horizontally or at an angle, the gravitational effect on the sensor’s internal components can create a slight shift compared to its standard vertical calibration position.

The DS2XX series of pressure switches includes a position correction or offset compensation feature (POSI or oFS) in the setup menu to easily correct this. This function allows you to re-zero the local display after installation.

To perform the correction:

- Ensure the device is installed and the pressure port is in a stable, depressurized state (e.g., vented to atmospheric pressure for a gauge pressure sensor).

- Navigate through the menu to the position correction function (

POSIoroFS). - Activate the function, typically by pressing both front panel buttons simultaneously. The device will then take the current pressure reading as the new zero point for the display.

It is critical to note that on the 2-wire 4-20mA models, this adjustment only affects the value shown on the local display. The 4-20mA analog output remains fixed to the original factory calibration and is not affected by this display zeroing function. This ensures that the raw, uncompensated signal is always transmitted to the control system, while the local display provides a convenient, corrected reading for technicians on-site.

Number of switches with ATEX version

Is it able to configure up to 2 contacts for 2 wire ATEX approved model?

Only 1 contact is possible with the ATEX IS 2 wire 4-20ma output version.

Liquid & gas compatibility

Can the the DS210 be used on liquids or gases, or both?

The DS210 can be used on gases, pressurized air and thin non aggressive liquid media. If you want to use a liquid it is best that you ask before ordering to determine whether it is compatible.

Negative & positive pressure ranges

I see that there are pressure ranges which are positive (100, 250…1000 mbar) and one which is negative (-1000 mbar), but is it possible to combine a negative & positive range in one device?

Yes it is also possible to offer custom compound ranges such as -1000 to +1000 mbar g or -250 to +500 mbar for example.

Output signal response time

What is the response time of the output signal?

- 2-wire: ≤ 10 msec

- 3-wire: ≤ 3 msec

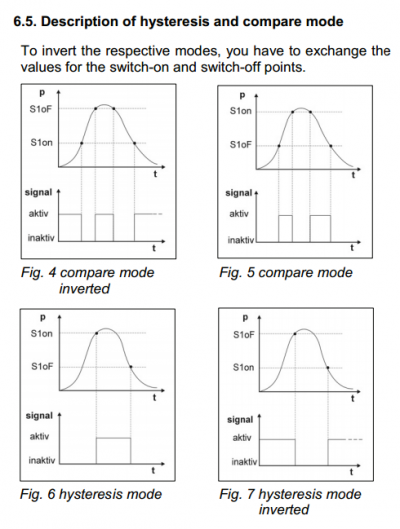

Hysteresis and compare modes

How does the switch work on the DS210 low pressure switch? e.g. could it be configured to switch at 16mbar and 30mbar gauge?

Each contact switch (you can order with up to 4 separate switches) can be used in compare or hysteresis mode.

Compare mode – Switch on at 16 mbar and switch off at 30 mbar, then switch on at 30 mbar and switch off at 16 mbar

Hysteresis mode – Switch on at 30 mbar and turn off at 16 mbar.

Both modes can be inverted if required.

Nitrogen gas up to 2psi

I am looking for a pressure transducer with a visual digital display to measure Nitrogen gas with a maximum temperature of 120°C over 0-2psi, with a 0-10Vdc output signal and installed on a 1/2 NPT process fitting. Also if at any point when measuring the pressure it went negative for a short period of time, say -0.5 psi max, would the sensor be damaged?

The DS210 would meet all your requirements, and it is possible to apply a negative pressure of -0.5 psi without causing any damage.

- SKU ID: s1-ds210-0002

- Pressure Range: 2

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0-10V (3 wire)

- Accuracy: 0.35%FS > 0.1 bar, 0.5%FS

- Switch Output: None

- Electrical Connection: DIN plug (0-10V 3 wire only)

- Process Connection: 1/2 NPT male

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: stainless steel 1.4404 (316L), silicon, Epoxy or RTV, glass

- Media Exposed Seals: FKM

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the DS210 Combined Low Pressure Switch, Indicator and Sensor in your application and request a quote.