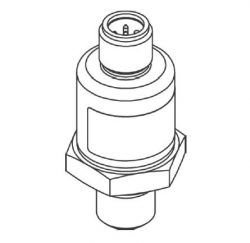

All welded stainless steel IO-Link interface pressure sensor with a low profile for use by mobile hydraulics manufacturers to measure hydraulic pressures up to 600 bar or 9000 psi.

Product Parameters

- Pressure Ranges: 0…6 to 600 bar gauge

- Output Signals: SIO / IO-Link

- Accuracy: 0.5% FS

- Electrical Connections: M12 x 1 4 pin, cable outlet

- Process Connections: G1/4 male DIN 3852

- Media Compatibility: Stainless steel 316L port and 17-4 PH diaphragm, FKM port seal

- Dimensions: 23.5mm diameter,

- Special Features: Short length, all welded wetted parts, no oil fill sensing module

Product Description

The DCT143 IO-Link pressure sensor is specifically designed for the unique demands of mobile hydraulic systems. Its compact, low-profile design combined with a short length makes it ideal for installation in space-constrained areas often found on mobile hydraulic equipment such as excavators, loaders, and agricultural machinery. The sensor’s all-welded, stainless steel construction ensures durability and reliable performance in harsh environments, able to withstand shock, vibration, and wide temperature variations typical of mobile applications.

A key advantage of the DCT143 is its oil-free sensing module. This design is particularly important in mobile hydraulics, where traditional oil-filled sensors can be susceptible to damage from cavitation. Cavitation, the formation of vapor bubbles in the hydraulic fluid due to rapid pressure changes, can generate shockwaves when those bubbles implode. These shockwaves can stress the internal components of oil-filled sensors, potentially leading to rupture or premature failure. The DCT143’s oil-free construction eliminates this vulnerability, ensuring greater reliability and a longer lifespan in demanding mobile hydraulic applications. While a slight improvement in dynamic response is a secondary benefit, the primary advantage of this design is its inherent resistance to cavitation and pressure spikes common in mobile hydraulic systems.

The IO-Link interface provides advanced communication capabilities, enabling seamless integration with modern control systems. This digital interface allows for remote configuration, parameterization, and diagnostics, simplifying setup and maintenance in the field. The IO-Link functionality also enables the transmission of rich data, including pressure values, temperature readings, and diagnostic information, facilitating predictive maintenance and optimizing machine performance. This is particularly advantageous in mobile hydraulics, where real-time data acquisition and analysis can improve efficiency, reduce downtime, and extend equipment life.

The DCT143 is compatible with a wide range of hydraulic fluids, thanks to its stainless steel 316L wetted parts and FKM seals. This ensures reliable operation in various mobile hydraulic applications, including those using biodegradable oils or aggressive fluids. The sensor’s high accuracy of 0.5% FS provides precise pressure measurement, essential for optimal control and performance of hydraulic systems.