In high-precision manufacturing and research environments, maintaining the correct volume of machine tool coolant is critical for process stability and tool longevity. Research engineers and technicians often utilize complex cutting fluid emulsions, such as mixtures of Blaser oil and water, which provide essential lubrication and cooling during machining. However, these fluids present unique measurement challenges due to their physical properties. They can become viscous, “milky,” and laden with particulate matter like swarf or sludge, which compromises standard immersion sensors. Reliable hydrostatic level monitoring in these tanks requires instrumentation specifically designed to resist clogging while delivering high-accuracy data to control systems.

A research technician at a manufacturing technology center required a solution to monitor the fluid level in a machine tool coolant tank. The application involved a specific “liquid tool” mixture of Blaser oil and water, an emulsion widely used in CNC machining for its stability and lubrication properties. The tank was open and vented, requiring a sensor capable of measuring the hydrostatic pressure created by the liquid depth.

The technical requirements were specific to the nature of the medium and the control system integration:

- Media Characteristics: The sensor needed to handle a mixture of oil and water (coolant emulsion). In machining environments, this fluid often carries metal fines and can develop a paste-like consistency at the tank bottom, making it aggressive toward standard internal-port sensors.

- Measurement Range: The application required measurement of relatively shallow depths (approximately 2 meters of water column), requiring a sensor with excellent sensitivity in low-pressure ranges.

- Output Signal: The control system required a standard industry output, specifically 4-20mA (2-wire) or 0-10V, to integrate with the machine’s PLC or monitoring measuring instrumentation.

- Installation Constraints: While the initial inquiry considered a suspended probe, the presence of particulates and the need for a permanent, robust installation pointed towards a solution that could withstand immersion or direct mounting without fouling.

To address the challenges of viscous coolant mixtures and potential particulate clogging, the LMK 351 series screw-in transmitter was identified as the optimal solution. Unlike standard pressure sensors that use an internal measuring port—which can easily become blocked by coolant sludge or metal swarf, the LMK 351 features a ceramic sensor with a flush-mounted diaphragm. This design eliminates “dead spaces” where debris could accumulate, making it specifically preferred for usage in viscous and pasty media.

The solution offered several key technical advantages for the research facility:

- Flush Diaphragm Technology: The capacitive ceramic sensor element is flush with the process connection. This ensures that the Blaser oil emulsion presses directly against the diaphragm without passing through a narrow channel, effectively preventing the clogging issues common with standard transmitters in dirty coolant applications.

- High Accuracy: For the precise monitoring required in a research environment, the sensor offers a standard accuracy of 0.35% FSO (Full Scale Output), with options for even higher precision.

- Chemical and Mechanical Resistance: The ceramic diaphragm (Al2O3 99%) is highly resistant to aggressive media. If the coolant chemistry becomes particularly aggressive, the series offers a PVDF pressure port option, though standard Stainless Steel 316L is typically sufficient for machining oils.

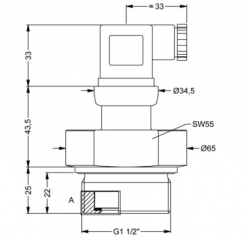

- Versatile Connectivity: The transmitter was configured with a standard 4-20mA 2-wire output to match the customer’s control requirements. It features a robust screw-in design (typically G 1 1/2″ or G 3/4″ flush) that allows for a secure, leak-proof installation at the bottom or side of the coolant tank.

By utilizing a flush-mounted ceramic sensor such as the LMK351 series, the facility could ensure continuous, maintenance-free level monitoring of their coolant tanks, preventing pump damage from low levels and ensuring consistent coolant concentration management.

LMK351 Screw-In Ceramic Flush Diaphragm Level Transmitter

- SKU ID: s1-lmk351-0007

- Pressure Range: 0 to 2 mH2O

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Accuracy: 0.35% FS

- Electrical Connection: DIN43650A plug IP65

- Process Connection: G1 1/2 male DIN3852 with flush diaphragm

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Ceramic Alumina Al2O3 99.9%

- Media Exposed Seals: FKM