Accurate measurement of shallow water bodies, such as rivers or catchment channels, presents a unique set of challenges for environmental engineers. When monitoring sites are remote, battery-powered, and subjected to wide seasonal temperature swings, the choice of sensor technology becomes critical. This application story details a scenario where a customer struggled with inconsistent data from a standard pressure sensor and outlines the engineering solution that resolved the issues of drift, non-linearity, and thermal instability. Key factors include the transition from absolute to gauge measurement and the correct venting of sealed installation pipes.

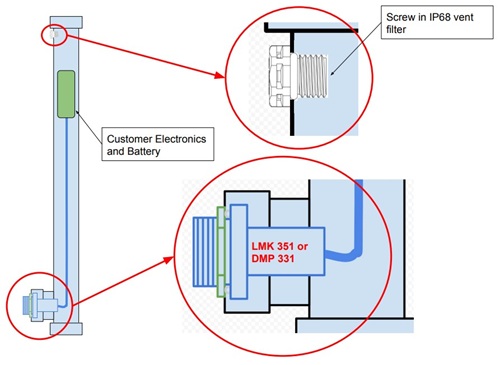

The customer required a reliable solution for monitoring water depth in a river with a maximum depth of approximately 2 meters. The installation utilized a PVC pipe acting as a stilling well, hammered vertically into the riverbed to protect the instrumentation and dampen water turbulence.

- Sealed Electronics Chamber: To protect the data logger and battery power source from moisture and rain, the top of the PVC pipe was completely sealed with a cap.

- Environmental Conditions: The sensor needed to withstand direct submersion for at least one year with temperature variations ranging from -10°C in winter to +30°C in summer.

- Power Constraints: The system operated on an intermittent cycle, powering up every 15 to 30 minutes to take a reading, requiring a sensor with a fast warm-up time to conserve battery life.

- Previous Failure Mode: The customer’s previous solution (a generic piezoresistive sensor) exhibited significant drift and non-linearity. Two identical sensors placed at the same depth provided different readings, and data drifted significantly when moved between locations or during temperature shifts.

The engineering team identified that the customer’s issues stemmed from two main causes: the use of an absolute pressure reference for a shallow application (leading to poor resolution) and the “gas spring” effect caused by the sealed pipe. The proposed solution involved the LMK 351 Screw-in Transmitter, a device specifically designed for small system pressure and level measurement.

- Ceramic Capacitive Technology for Stability: Unlike the customer’s previous sensor, the LMK 351 utilizes a capacitive ceramic sensor element. Ceramic sensors are naturally resistant to thermal effects and offer superior long-term stability compared to oil-filled piezoresistive sensors, which can suffer from thermal drift. This was crucial for the customer’s requirement of a one-year maintenance-free operational life in varying river temperatures. The ceramic diaphragm is flush-mounted, which also prevents sediment buildup that can occur in river environments.

- Optimizing Resolution with Gauge Reference: The customer had initially considered an absolute sensor to avoid venting issues. However, using an absolute sensor for a 2-meter water column (approx. 200 mbar) means the sensor must measure the atmospheric pressure (approx. 1000 mbar) plus the water pressure. This “down-ranging” effectively reduces the usable signal resolution. The solution utilized a gauge reference LMK 351 with a 0–250 mbar range. This ensures the full output signal (e.g., 0-10V) is dedicated solely to measuring the water depth, providing maximum accuracy.

- Solving the “Sealed Pipe” Issue with IP68 Venting: A critical flaw in the customer’s original design was the completely sealed PVC pipe. As the water level rises or temperature changes, the air trapped inside a sealed pipe compresses or expands, creating internal pressure that fights against the water pressure, causing non-linear readings. To fix this while maintaining moisture protection, the solution integrated a breathable IP68 vent filter installed into the side of the pipe.

- Vent Function: The filter allows the internal air pressure to equalize with the atmosphere, ensuring the gauge reference sensor works correctly.

- Moisture Protection: The IP68 rating prevents rain or river splash from entering the electronics enclosure.

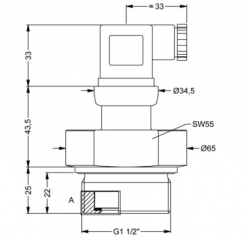

- Installation: The sensor is screwed through the pipe wall using a standard G 1 1/2″ fitting or mounted internally with a vented cable assembly.

- Electrical and Flow Considerations: To accommodate the customer’s low-voltage electronics, the LMK 351 can be configured with a 3-wire 0-10V output. For flow dynamics, the sensor head is positioned directionally to minimize dynamic pressure errors caused by the river current, ensuring the reading represents static depth rather than velocity pressure.

LMK351 Screw-In Ceramic Level Transmitter

- SKU ID: s1-lmk351-0008

- Pressure Range: 0 to 2 mH2O

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 0-10V (3 wire)

- Accuracy: 0.35% FS

- Electrical Connection: IP68 (temp immersion) seal with 2m of cable

- Process Connection: G1 1/2 male DIN3852 with flush diaphragm

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Ceramic Alumina Al2O3 99.9%

- Media Exposed Seals: FKM