Ensuring the operational readiness of high-pressure seawater pumps is vital for cleaning and maintenance duties aboard merchant vessels. This application requires pressure instrumentation that can provide accurate data while surviving the uniquely harsh conditions of the marine environment, including constant vibration, corrosive attack from salt water, and permanent submersion.

- Application: Monitoring pump inlet (10 bar) and outlet (250 bar) pressure on a ship’s high-pressure seawater washing system.

- Challenge: The pressure sensors must be permanently installed, capable of being continuously submerged in corrosive seawater, and withstand the demanding marine environment.

- Solution: A marine-approved pressure transmitter featuring a seawater-resistant copper-nickel alloy housing and a robust ceramic sensing diaphragm.

Monitoring the performance and efficiency of high-pressure pump systems is a critical task in many industrial settings, but it presents unique challenges in a marine environment. For operators of merchant vessels, high-pressure seawater systems are essential for tasks such as washing the main deck and cleaning out vast cargo holds between shipments. The reliable operation of these pumps, which can generate pressures up to 250 bar, depends on accurate pressure measurement at both the low-pressure inlet and the high-pressure outlet. The instrumentation used must not only provide continuous, reliable data but also endure one of the most corrosive and demanding environments on earth: permanent submersion in seawater.

A customer required a pressure monitoring solution for their high-pressure washing system installed on merchant vessels. The system uses a powerful pump to draw in seawater at approximately 10 bar and pressurise it to 250 bar for cleaning operations. After use, the entire system is flushed with fresh water. The primary challenge was sourcing pressure transmitters that could be permanently installed on the pump’s inlet and outlet piping, where they would be constantly submerged in seawater. Key requirements included exceptional durability, suitability for the marine environment, and a preference for using the same instrument model for both the 10 bar and 250 bar measurement points to simplify maintenance and spare parts inventory.

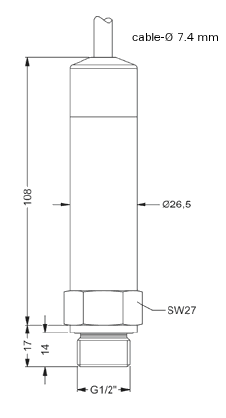

The proposed solution was the DMK457 series pressure transmitter, a device specifically designed and approved for shipbuilding and offshore applications. For the 10 bar pump inlet and the 250 bar outlet, two versions of the DMK457 were configured, meeting the customer’s desire for a single model platform. The transmitters feature an industry-standard 4-20mA 2-wire output for straightforward integration into the vessel’s control systems. The defining feature of this solution is its exceptional resilience to the marine environment. The transmitter is available in a fully submersible version with a housing and pressure port constructed from a copper-nickel-iron alloy (CuNi10Fe1Mn), a material renowned for its resistance to seawater corrosion. This construction directly addressed the critical requirement for continuous operation while submerged. Further enhancing its durability is the use of a robust ceramic diaphragm (Al₂O₃ 96%) as the pressure-sensing element. This ceramic sensor is inherently resistant to corrosion and abrasion, making it ideal for direct contact with seawater, which may contain sand or other particulates. The instrument’s design is validated by its Germanischer Lloyd (GL) and Det Norske Veritas (DNV) shipping approvals, confirming it has passed rigorous testing for vibration and stability, ensuring a long operational life aboard a working vessel. By combining a seawater-resistant housing, a durable ceramic sensor, and official marine certifications, this solution provides the necessary reliability for monitoring critical pump systems on the high seas.

DMK457 Submersible Seawater Resistant Pressure Transmitter

- Pressure Range: 0 to 10 bar (Inlet) / 0 to 250 (Outlet)

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4 – 20 mA, 2-wire

- Accuracy: 0.5% FS

- Electrical Connection: TPE cable IP68 seawater compatible housing (permanent immersion)

- Cable Length: 20

- Cable Length Units: metres (m)

- Process Connection Material: CuNi10Fe1Mn Seawater Compatible

- Process Connection: G1/2 DIN3852

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM