A ferry operator faced a critical maintenance challenge when multiple level sensors across various onboard tanks began to fail. With no available technical information on the legacy sensors, a direct replacement was not possible, necessitating a new, fully-certified solution. The primary challenge was to find a single sensor model versatile enough to handle different media types, from freshwater to fuel and sewage, while holding all the required marine-grade certifications for safety and reliability at sea.

- Application: Continuous level monitoring in multiple service tanks on a commercial ferry.

- Challenge: Replacing undocumented, failing sensors with a reliable, certified alternative.

- Media: A diverse range of liquids including freshwater, fuel, sludge, and sewage.

- Requirement: Mandatory marine type-approvals for onboard use.

- Solution: An externally mounted, marine-approved hydrostatic level transmitter with a robust ceramic sensing element.

A client operating a fleet of commercial ferries required a reliable solution for level measurement in various onboard service and storage tanks. The existing sensors, which were connected to a central PLC and HMI system, were failing without any available documentation, making it difficult to source like-for-like replacements. The application demanded a versatile sensor capable of measuring levels up to 2,380 mmH₂O across tanks containing a wide array of media, including freshwater, fuel, sludge, and sewage. A key, non-negotiable requirement was that any new instrumentation must possess formal marine type-approvals to comply with maritime regulations. The installation method required an externally mounted sensor with a threaded process connection, rather than a submersible probe dropped in from the top of the tank.

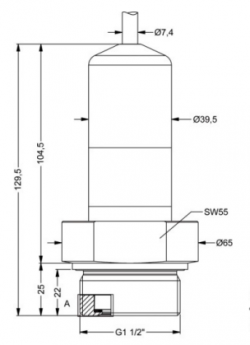

The proposed solution was the LMK 458H series hydrostatic level transmitter, specifically configured for marine and offshore applications. This sensor series carries an extensive list of shipping approvals, including those from Lloyd’s Register (LR), DNV GL, and the American Bureau of Shipping (ABS), satisfying the client’s most critical requirement. The heart of the transmitter is a capacitive ceramic sensor with an aluminium oxide (Al2O3) diaphragm. This technology provides two essential benefits for this application: high resistance to overpressure events and exceptional compatibility with the chemically diverse and potentially corrosive media found in the ferry’s tanks. The selection of a screw-in version with a G1 1/2″ process thread allows for secure, external mounting at the base of the tanks, simplifying installation and future maintenance.

The LMK 458H provides significant advantages tailored to the demanding marine environment. While the standard 316L stainless steel housing is suitable for many liquids, an optional Copper-Nickel-Iron (CuNiFe) housing offers superior resistance to seawater corrosion, ensuring long-term durability. Although the client indicated that HART communication was not essential, this feature provides valuable functionality for optimising performance. Using a HART interface, technicians can remotely adjust the sensor’s electronic damping settings. This is particularly useful for stabilising the 4-20mA output signal in applications where liquid sloshing may occur due to the vessel’s movement in rough seas. The sensor’s high long-term stability and robust build, designed to withstand vibration according to DNV GL Class B standards, ensure dependable performance and reduce the lifecycle cost by minimising downtime and the need for frequent recalibration.

LMK458 Marine Certified Screw-On Hydrostatic Level Transmitter

- Part No: 76F-2500-1-5-C-H-1-4-1-003-000

- Pressure Range: 0 to 2.5 mH2O g

- Output Signal: 4 – 20mA / 2-wire, HART communications

- Accuracy: <±0.1% FS

- Installation Type: Screw-in version (G1 1/2″ thread)

- Housing Material: Stainless steel 1.4404 (316L)

- Diaphragm Material: Ceramic Al2O3 99.9%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 3m

- Optional Extras: none