A systems integrator specializing in desalination projects required a durable and reliable pressure transmitter for a new containerized reverse osmosis (RO) system. The primary challenge was sourcing an instrument capable of withstanding the highly corrosive effects of high-pressure seawater while providing an accurate signal to the master control system. The solution involved a pressure transmitter constructed from specialized materials designed specifically for harsh marine environments.

- Application: High-pressure monitoring in a seawater reverse osmosis (RO) system.

- Media: Seawater at a maximum temperature of 35°C.

- Pressure Range: Operating between 60 and 80 bar gauge.

- Key Challenge: Selecting wetted materials with proven long-term resistance to corrosion from high-chloride seawater.

A customer designing a compact, containerized reverse osmosis system needed to precisely monitor the high-pressure side of the process. In desalination via reverse osmosis, seawater is pressurized to levels often exceeding 60 bar to overcome the natural osmotic pressure and force fresh water through a semi-permeable membrane, leaving concentrated brine behind. Accurate and stable pressure measurement is critical for controlling pump output, ensuring process efficiency, and protecting the RO membranes from damage. The project’s core technical requirement was that all wetted parts of the sensor must be impervious to the corrosive nature of seawater. Standard stainless steel grades are prone to pitting, crevice corrosion, and chloride stress corrosion cracking in such environments, leading to premature failure. The instrumentation also needed to integrate seamlessly with a Siemens S7-1200 PLC, which required a standard industrial analogue output signal for process control.

The TPTa series pressure transmitter was proposed as the ideal solution to meet these demanding requirements. The key to its suitability lies in the material selection for its wetted parts. The transmitter’s housing and process connection are manufactured from UNS S31803 duplex stainless steel. This material, also known as Duplex 2205, possesses a mixed microstructure of austenite and ferrite, giving it a superior combination of strength and corrosion resistance compared to common austenitic steels like 316L. Specifically, its high chromium, molybdenum, and nitrogen content provides excellent resistance to chloride-induced corrosion, making it a premier choice for marine and offshore applications. This directly addressed the customer’s primary concern about long-term reliability in contact with seawater. The material choice was complemented by Viton (FKM) seals, which offer excellent thermal and chemical resistance compatible with the operating conditions. The sensor’s 0-80 bar pressure range comfortably covers the application’s operating window, and its standard <±0.25% full-scale accuracy provides the necessary precision for the PLC control loop. The 4-20mA two-wire output is the industry standard for robust, noise-immune signal transmission, ensuring flawless communication with the Siemens S7-1200 controller.

TPTa Seawater Compatible Pressure Transmitter

- Pressure Range: 0 – 80 Bar

- Pressure Datum: Gauge

- Output Type: 4-20mA / 2-wire

- Power Supply: 9-32V dc

- Accuracy Class: 0.25% FS

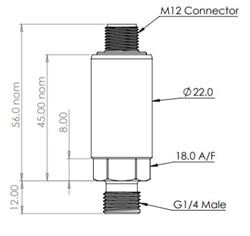

- Electrical Connection: M12, 4-pin connector

- Process Connection: G1/4″ male DIN 3852

- Housing Material: UNS31803 Stainless Steel

- Seal Material: Viton

- Special Options: None