Wet wet differential pressure sensor with a high overpressure rating on both positive and negative side port for protection against accidental diaphragm damage.

Product Parameters

- Pressure Ranges: from 200 mbar up to 16 bar differential

- Static Line Pressures: from 0.2 up to 16 bar including on one port only

- Accuracy: ±0.5% of full scale (IEC 60770)

- Output Signal: 4-20mA or 0-10V

- Electrical Connections: DIN43650A plug and Brad Harrison mini change

- Pressure Connection: G1/2, 7/16 UNF male and G1/4 female

- Special Features: high overpressure

- Special Options: ATEX approved intrinsic safety

- Media Compatibility: Stainless steel 316L, FKM seals

- Dimensions: 48 x 40 x 40 mm excluding connectors

- Weight: ~250g

Product Description

The DMD331 is an unconventional design for measuring differential pressure, in that two separate pressure sensors are utilised inside to measure the pressure at two ports. The difference between the two measurements are subtracted to create the differential pressure output signal.

The main advantage of this type of sensor is that full line pressure can be applied to one side without damaging the sensor. This also makes it unnecessary to incorporate a complex mechanical protection device, keeping size to a minimum dimensions and reduces the cost compared to more conventional differential pressure sensor technology.

The DMD 331 has 6 nominal pressure range from 0-0.2 bar up to 0-16 bar differential and each range has a choice of sub-ranges which can be selected depending on the required level of overpressure rating.

The lowest possible scaled pressure range is 0 to 20 mbar differential and this can withstand a 500 mbar overpressure and 200 mbar continuous line pressure on either the positive or the negative port.

The differential pressure signals can be transmitted as linear 4-20mA or 0-10Vdc analog output.

The all stainless steel 316L DMD 331 wet wet differential pressure sensor is suitable for use with compatible liquids down to relatively low differential pressures.

The compact size of the DMD-331 dp sensor makes it ideal for use in dense instrumentation packages where there is very little space between components for fitting a conventional dp transmitter.

Product Applications

Self cleaning water filter

Monitor the differential pressure drop across a water filter to determine when it is necessary to perform the self cleaning process.

- SKU ID: s1-dmd331-0002

- Part No: 730-D-6000-1-8-100-J00-1-000

- Differential Pressure Range: 0 to 0.6

- Units: bar

- Maximum Line Pressure: 6

- Units: bar

- Output Signal: 4 – 20mA, 2-wire

- Accuracy: 1% full scale

- Electrical Connection: DIN plug and socket

- Process Connection: G1/4 female

- Media Compatibility: Stainless steel 316L, FKM seals

Oil filter health monitoring

Measure the differential pressure either side of an oil filter to monitor when it needs to be changed or cleaned.

- SKU ID: s1-dmd331-0005

- Part No: 730-D-3001-1-5-100-200-1-000

- Differential Pressure Range: 0 to 3

- Units: bar

- Maximum Line Pressure: 6

- Units: bar

- Output Signal: 4 – 20mA, 2-wire

- Accuracy: 0.5% full scale

- Electrical Connection: DIN plug and socket

- Process Connection: G1/2 male EN837

- Media Compatibility: Stainless steel 316L, FKM seals

Part Numbers

730-E-2501-1-5-100-200-1-000

- SKU ID: s1-dmd331-0004

- Part No: 730-E-2501-1-8-100-200-1-000

- Differential Pressure Range: 2.5

- Units: bar

- Maximum Line Pressure: 16

- Units: bar

- Output Signal: 4 – 20mA, 2-wire

- Accuracy: 1% full scale

- Electrical Connection: DIN plug and socket

- Process Connection: G1/2 male EN837

- Media Compatibility: Stainless steel 316L, FKM seals

Product Help

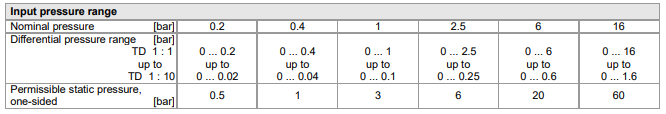

Max line pressures and dp ranges

What are the maximum line pressures and differential pressure ranges that are suitable for this device?

The DMD331 is not a conventional DP type sensor, it uses two pressure sensors internally and subtracts the difference, therefore this limits the max line pressure for each DP range, due to the nominal range of each of the pressure sensors.

The permissible static pressure in the table below represents the maximum over-pressure on one side which is intended for protection from brief abnormal operating conditions, and the nominal pressure represents the maximum static line pressure and the 100% base pressure range.

4-20mA range adjustment

Can the 4-20 mA range be varied e.g we would like it to measure over 0 to 3 bar?

The range is fixed and set in the factory and can’t be changed by the user. Alternatively you could consider the DPT200 rangeable dp transmitter which allows the user to vary the 4-20mA output via HART communications or the built-in manual push buttons.

Nominal range for 0-2 bar dp with 10 bar line pressure

I have a 10 bar line pressure and want to measure a pressure drop which ranges from 0-2 bar, which nominal range should I select for the DMD 331?

To measure a 0 to 2 bar pressure drop, you can specify either 2.5, 6, or 16 bar nominal range for the sensor. However the 2.5 bar range only has a line pressure rating of 2.5 bar max, and therefore this would not be suitable since it is below the required 10 bar line pressure. Likewise a 6 bar nominal range would be limited to 6 bar line pressure. Therefore a 16 bar nominal range would provide ample line pressure capability up to 16 bar. The sensor output is then down-scaled in the factory to 2.5 bar for the 4-20mA differential output signal.

The table shows the standard pressure range options:

Nominal and Differential pressure range meaning

On the last page of the data sheet there are options for nominal pressure range and differential pressure , what does this mean and what nominal pressure do I need if I need a differential of 6 bar?

This sensor is different to a typical dp sensor in that it utilises two pressure sensing modules, one for each connection port, and subtracts the two pressure readings to determine the differential pressure reading. The main advantage to this style of dp sensor is it is possible to provide high one-sided over-pressure protection without relying on extra mechanical mechanisms, which increases cost, size and complexity.

The nominal pressure range refers to the max pressure range of each pressure sensor. For each nominal pressure range it is possible to provide a choice of differential pressure ranges down 1/10 of the nominal pressure range. The main reason for this is to provide the optimal dp range for the line pressure of the pressure system. For example if your system pressure is 16 bar, the minimum nominal pressure range you could choose would be 1.6 bar.

- SKU ID: s1-dmd331-56-28045

- Part No: 730-E-1601-1-8-100-J00-1-000

- Differential Pressure Range: 0 to 1.6

- Units: bar

- Maximum Line Pressure: 16

- Units: bar

- Output Signal: 4 – 20mA, 2-wire

- Accuracy: 1% full scale

- Electrical Connection: DIN plug and socket

- Process Connection: G1/4 female

- Media Compatibility: Stainless steel 316L, FKM seals

Input supply voltage for IS 4-20mA signal

What is the input voltage for the DMD331 with 4-20mA output and intrinsic safety?

Any voltage between 14-28Vdc between the connections to the transmitter.

Jet-A kerosene fuel filter

We are looking for a intrinsically safe 4-20mA sensor to measure differential pressure across a Jet-A kerosene filter, the line pressure runs up to 75 psi and the maximum DP we need to measure is 40 psi?

The BD Sensors DMD 331 is available in an ATEX approved IS version, and the 4-20mA output can be scaled to exactly 0 to 40 psi differential pressure, which can be used on line pressure up 87 psi.

- SKU ID: s1-dmd331-0003

- Part No: 730-D-9999-E-5-100-J00-1-000

- Differential Pressure Range: 40

- Units: psi

- Maximum Line Pressure: 87

- Units: psi

- Output Signal: 4 – 20mA, ATEX / IECEx IS, 2-wire

- Accuracy: 0.5% full scale

- Electrical Connection: DIN plug and socket

- Process Connection: G1/4 female

- Media Compatibility: Stainless steel 316L, FKM seals

100 kPa range with 6 bar overpressure rating

What is the limit on the differential pressure that can be applied to a DMD331 transducer, we have a max upstream pressure of 6 bar, and the differential pressure range is 0 to 100 kPa, so can it withstand the 6 bar?

If you select a 6 bar (600 kPa) nominal pressure with differential pressure scaling of 0 to 1 bar (100 kPa) a 6 bar differential will not damage the sensor.

The max pressure that can be applied to both ports, or one side only, without damaging the sensor is 6 bar g.

e.g. High side port = 6 barg, Low side port = 5 barg, will read 1 bar diff, in range, no damage

e.g. High side port = 6 bar g, Low side port = 0 bar g, out of reading range, but no damage

Engine intake & exhaust flow differential air pressure

I have an engine which needs a differential pressure sensor to measure air flow between the intake and exhaust manifolds that is close to meeting the following requirements:

- IMP range (intake side): 100 – 300 kPa absolute

- EMP range (exhaust side): 100 – 420 kPa absolute

- Engine delta P range: -15 to 160kPa

- Accuracy: 2%

- Response time: 4.7 ms

We would suggest the following DMD331 options for measuring the air flow differential pressure between air intake and exhaust which would have a maximum intake or exhaust side pressure rating of 600 kPa absolute:

- SKU ID: s1-dmd331-0001

- Part No: 730-C-9999-1-5-100-J00-1-000

- Differential Pressure Range: -15 to 160

- Units: kPa

- Maximum Line Pressure: 6

- Units: bar

- Output Signal: 4 – 20mA, 2-wire

- Accuracy: 0.5% full scale

- Electrical Connection: DIN plug and socket

- Process Connection: G1/4 female

- Media Compatibility: Stainless steel 316L, FKM seals

- Optional Extras: Compound range output signal (-P1 to +P2)

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the DMD331 Compact Differential Liquid Pressure Sensor in your application and request a quote.

"*" indicates required fields