Marine approved level transmitter with 4-20mA current loop output for measuring the level of contents inside a ships ballast, fuel, liquid cargo or wastewater tanks with optional all CuNiFe construction for sea-water compatibility in ranges from 0.4 mH2O to 200mH2O gauge or absolute.

The LMK 458 marine level transmitter has a capacitive ceramic sensing diaphragm which is compatible with sea water and salt spray when the copper nickel alloy option is specified.

The LMK458 marine level transmitter is LR (Lloyd´s Register), GL (Germanischer Lloyd), DNV (Det Norske Veritas), ABS (American Bureau of Shipping) and CCS (China Classification Society) approved for marine use and can be used on seawater ballast, fuel, oil, service and waste water systems.

ATEX approved for intrinsically safe use in hazardous environments the LMK-458 marine approved level transmitter can also be used on ship systems which are handling flammable and volatile chemicals such as oil, gas, liquid petroleum gas (LPG) and liquid natural gas (LNG).

The LMK-458 ballast level sensor comes in a range of pressure fittings for either lowering into a tank, screwing into a pipe or flange mounting to the wall of a tank.

Product Parameters

- Pressure Ranges: 0.4 up to 200 mWG, 40mbar to 20 bar gauge or absolute

- Accuracy: 0.25% full scale with optional 0.1% for ranges above 6mH2O only

- Output Signal: 4-20mA current

- Electrical Connection: IP68 submersible TPE cable outlet

- Pressure Connections: flange or screw-in with flush diaphragm

- Media Compatibility: Stainless steel 316L or CuNi10Fe1Mn body, Ceramic Al2O3 (96%) diaphragm, FKM, FFKM or EPDM seal gasket plus selected cable jacket

- Dimensions: 39.5 mm diameter

- Weight: 650 g minimum

- Special Features: DNV & GL marine approved for use on ships ballast, fuel and liquid cargo tanks

- Special Options: CuNi10Fe1Mn construction for seawater use, ATEX IS approval, prepared for pipe mounting, integrated PT100 temperature sensor, HART communications

Product Description

The harsh corrosive environment which level sensors are subjected to on a ship, call for a corrosion resistant construction and robust mechanical design.

The materials employed need to withstand the effects of relentless exposure to seawater and salt spray when installed on the deck or in the ballast tanks of a ship. The design must meet the mechanical integrity requirements for pressure measurement and be robust enough to survive in an uncompromising heavy industry environment.

The LMK458 tank level transmitter measures the hydrostatic pressure of a wide range of liquids that are found on marine vessels such as oil tankers and bulk carriers.

Installation types

This versatile marine approved hydrostatic level transmitter has many different styles for mounting, starting with the simplest which involves dropping the LMK-458 level transmitter down a stilling well to measure the level whilst permanently submerged in the tank. This is useful for installations where there is no service access to the side of the tank.

If a stilling well is not available, the submersible level transmitter has a mounting bracket option for fixing into position on the inside of the tank.

Where maintenance access between tank bulkheads is possible the LMK 458 marine level transmitter can be mounted with a G11/2 male thread or with a flange mountable fitting.

Sea water compatibility

For seawater systems the LMK-458 ballast level transmitter can be made from Copper Nickel alloy construction which has high corrosion resistance to sea-water and can be used on ballast tanks and other seawater pumping systems.

Hazardous cargo

If the vessel is carrying hazardous material which requires IS approved instrumentation such as oil tankers, LPG ships or LNG ships, the LMK 458 level pressure transmitter can be supplied with ATEX approval for intrinsically safe use.

Flush chemical resistant diaphragm

The LMK458 marine approved hydrostatic level transmitter incorporates a capacitive ceramic sensing diaphragm that has a high overpressure. This is useful for cargo ships which carry a variety of chemicals and need to clean the inside of the tank with high pressure caustic solutions.

The flush ceramic diaphragm is also well suited for use with waste water, abrasive material, viscous fluids and corrosive chemicals because of the hardness and inert properties of alumina ceramic.

Marine approved

For added assurance of the LMK458 hydrostatic pressure transmitters suitability for use in shipbuilding applications it has been certified by Germanischer Lloyd (GL) and Det Norske Veritas (DNV) for marine use.

Level measurement

The LMK-458 marine approved level transmitter can measure hydrostatic pressure from 0.4 up to 250 metres of water gauge with an accuracy of ±0.175% full scale best straight line non-linearity, hysteresis and repeatability. The capacitive ceramic sensor provides a high overpressure rating as much as 10 times for some ranges which helps protect the sensor from surge pressures when the tank is being filled or cleaned.

Multi-purpose

Shipbuilders require flexibility, high reliability and corrosion resistance from the instrumentation they install and the LMK458 level transmitter has been designed for this task with many possible configurations for most level measurement applications onboard a sea vessel.

Product Applications

Marine vessel tank level

- Diesel fuel

- Fresh water

- Grey water

- Black water

- Sea water ballast

- Liquid cargo

Heated heavy fuel oil content management

Tankers and cargo ships have several tanks in which fuel is stored and the level is monitored

The fuel required to drive the engines consists of several components including heavy oil, which can only be pumped from a temperature of greater than 50°C. Level measurement takes place under extreme conditions, and the relevant measuring technology must be extremely robust and capable of overloading.

Anti-Heeling systems

anti-heeling systems are installed to prevent ships from tilting when manoeuvring and in the event of one-sided loading or storms. These systems compensate for the extreme positions by pumping liquids around in laterally mounted tank containers. The levels in the tanks are permanently monitored, and are used to control the pumping systems.

Oil tanker ballast

Large oil tanker ship ballast tanks up to 30 metre depth.

- SKU ID: s1-lmk458-0006

- Part No: 765-3001-K-1-2-E-1-4-2-040-000

- Pressure Range: 0 to 30

- Units: mH2O

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE (125degC max)

- Cable Length: 40

- Cable Length Units: Metres (m)

- Optional Extras: ATEX Intrinsic safety approval

Sea vessel oil tank hydrostatic pressure & temperature

Measure hydrostatic pressure and temperature of fuel oil tanks vented to atmospheric pressure on a sea vessel. Lower the sensor inside the oil tank and suspend from the cable gland flange assembly fitted to the top of the tank.

- SKU ID: s1-lmk458-0008

- Part No: 765-4000-1-1-2-1-1-4-2-006-013 / DN25

- Pressure Range: 0 to 0.4

- Units: bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone & assembly flange

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 6

- Cable Length Units: Metres (m)

- Optional Extras: PT100 integral temperature sensor

- Optional Extras: DN25/PN40 assembling flange with cable gland

Oil platform concrete leg

Measure the level of seawater in the concrete leg of an offshore oil production platform.

- SKU ID: s1-lmk458-0009

- Part No: 765-2501-K-1-2-E-1-4-2-050-000

- Pressure Range: 2.5

- Units: bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 99.9%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 50

- Cable Length Units: Metres (m)

- Optional Extras: ATEX Intrinsic safety approval

Part Number Configuration Examples

Examples of LMK 458 part numbers and associated product specification configuration descriptions.

761-1601-1-3-C-1-1-4-3-025-000

- SKU ID: s1-lmk458-0034

- Part No: 766-1601-1-3-C-1-1-4-2-025-000

- Pressure Range: 0 to 16

- Units: mH2O

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Flange mounted version (Flange excluded)

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 99.9%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 25

- Cable Length Units: Metres (m)

768-D243-K-1-2-1-3-4-2-008-000

- SKU ID: s1-lmk458-0026

- Part No: 768-D243-K-1-2-1-3-4-2-008-000

- Pressure Datum: Absolute, in Bar

- Pressure Range: 0.8 to 2.4 bar

- Housing Material: Copper-Nickel-Alloy (CuNi10Fe1Mn)

- Type of Construction: Submersible Probe

- Diaphragm: Ceramic Al2O3, 96%

- Output: 4 – 20mA / 2-wire

- O Ring Seals: EPDM

- Electrical Connection: TPE Cable

- Accuracy: 0.125% / FS (BFSL)

- Cable Length: 8 metre TPE

- Special Options: None

- Supply Voltage: 9 – 32V dc

- Thermal Errors (TZS/TSS): ±0.01% FSO / °C

- Media Temperature: -25 to +125°C

- Approvals: Germanischer Lloyd (GL) and Det Norske Veritas (DNV)

768-D449-1-3-2-E-1-4-2-006-000

- SKU ID: s1-lmk458-0027

- Part No: 768-D449-1-3-2-E-1-4-2-006-000

- Pressure Datum: Absolute, in Bar

- Pressure Range: 0.8 to 1.6 bar

- Housing Material: Stainless Steel 1.4571 (316Ti)

- Type of Construction: Flange Version

- Diaphragm: Ceramic Al2O3, 96%

- Output: 4 – 20mA / 2-wire, Intrinsically Safe (ATEX)

- O Ring Seals: FKM

- Electrical Connection: TPE Cable

- Accuracy: 0.25% FS

- Cable Length: 6 metre TPE

- Special Options: None

- Supply Voltage: 10 – 28V dc

- Thermal Errors (TZS/TSS): ±0.01% FSO / °C

- Media Temperature: -25 to +125°C

- Approvals: ATEX, Germanischer Lloyd (GL) and Det Norske Veritas (DNV)

765-2501-K-5-2-1-1-2-2-008-000

- SKU ID: s1-lmk458-0028

- Part No: 765-2501-K-5-2-1-1-2-2-008-000

- Pressure Range: 2.5 bar g

- Pressure Connection: G11/2 male flush DIN3852

- Housing and Pressure Connector Material: CuNi10Fe1Mn

- Seals exposed to media: FKM (standard)

- Accuracy: 0.25% FS (standard)

- Cable Type: PUR

- Length of Cable (metres): 8

768-D243-K-1-2-1-3-4-2-010-000

- SKU ID: s1-lmk458-0029

- Part No: 768-D243-K-1-2-1-3-4-2-010-000

- Pressure Range: 0.8 to 2.4 bar abs

- Pressure Connection: Protection cap (immersible)

- Housing and Pressure Connector Material: CuNi10Fe1Mn

- Seals exposed to media: EPDM

- Accuracy: 0.25% FS (standard)

- Cable Type: TPE (standard)

- Length of Cable (metres): 10

768-D291-K-5-2-1-1-4-2-005-546

- SKU ID: s1-lmk458-0030

- Part No: 768-D291-K-5-2-1-1-4-2-005-546

- Pressure Range: 0.8 to 3.3 bar abs

- Pressure Connection: G11/2 male flush DIN3852

- Housing and Pressure Connector Material: CuNi10Fe1Mn

- Seals exposed to media: FKM

- Accuracy: 0.25% FS (standard)

- Cable Type: TPE (standard)

- Length of Cable (metres): 5

- Special Options: Pressure port with FFKM

768-D290-K-1-2-1-1-4-2-010-000

- SKU ID: s1-lmk458-0031

- Part No: 768-D290-K-1-2-1-1-4-2-010-000

- Pressure Datum: Absolute, in bar

- Pressure Range: 0.8 to 1.8 bar

- Housing Material: Copper-Nickel-Alloy (CuNi10Fe1Mn)

- Type of Construction: Submersible Probe

- Diaphragm: Ceramic Al2O3, 96%

- Output: 4 – 20mA / 2-wire

- O Ring Seals: FKM

- Electrical Connection: TPE Cable

- Accuracy: 0.25% FS

- Cable Length: 10 metre TPE

- Special Options: None

- Supply Voltage: 9 – 32V dc

- Thermal Errors (TZS/TSS): ±0.01% FSO / °C

- Media Temperature: -25 to +125°C

- Approvals: Germanischer Lloyd (GL) and Det Norske Veritas (DNV)

765-1001-K-1-2-1-3-4-2-010-000

- SKU ID: s1-lmk458-0032

- Part No: 765-1001-K-1-2-1-3-4-2-010-000

- Pressure Range: 1

- Units: bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: EPDM

- Cable Type: TPE (125degC max)

- Cable Length: 10

- Cable Length Units: Metres (m)

768-D243-1-5-2-1-1-4-2-008-000

- SKU ID: s1-lmk458-0033

- Part No: 768-D243-1-5-2-1-1-4-2-008-000

- Pressure Range: 0.8 to 2.4

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: G1 1/2 male screw-in version

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 8

- Cable Length Units: Metres (m)

Discontinued Part Number Replacements

List of older part numbers where a configuration option is no longer available, with the closest replacement part number and configuration description.

LMK 457 to equivalent LMK 458 part number configurations

Examples of new LMK 458 part numbers and the related product specification configuration descriptions to replace older and now obsolete LMK 457 part numbers.

763-B200-1-1-2-1-1-4-3-005-000

- SKU ID: s1-lmk458-0017

- Part No: 768-B200-1-1-2-1-1-4-2-005-000

- Pressure Range: 0.8 to 1.2

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 5

- Cable Length Units: Metres (m)

765-1600-1-1-2-1-3-4-2-008-000

What is the LMK458 specification for the part number 765-1600-1-1-2-1-3-4-2-008-000?

- SKU ID: s1-lmk458-0007

- Part No: 765-1600-1-1-2-1-3-4-2-008-000

- Pressure Range: 0.16

- Units: bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: EPDM

- Cable Type: TPE (125degC max)

- Cable Length: 8

- Cable Length Units: Metres (m)

763-B200-K-1-2-1-1-4-3-005-000

- SKU ID: s1-lmk458-0018

- Part No: 768-B200-K-1-2-1-1-4-2-005-000

- Pressure Range: 0.8 to 1.2

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 5

- Cable Length Units: Metres (m)

760-1601-K-1-2-1-3-4-3-008-000

What is the specification for the LMK457 part number 760-1601-K-1-2-1-3-4-3-008-000?

The LMK457 is obsolete and has been replaced by the LMK458, and the like for like new part number & spec is as follows:

- SKU ID: s1-lmk458-0005

- Part No: 765-1601-K-1-2-1-3-4-2-008-000

- Pressure Range: 1.6

- Units: bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: EPDM

- Cable Type: TPE (125degC max)

- Cable Length: 8

- Cable Length Units: Metres (m)

760 1001 K 1 2 1 3 4 3 005 000

We need to source this part number 760 1001 K 1 2 1 3 4 3 005 000 but no one seems to know what it is?

It belongs to the LMK 457 which has been superseded by the LMK 458, and the new equivalent part number and description is below:

- SKU ID: s1-lmk458-0003

- Part No: 765-1001-K-1-2-1-3-4-2-005-000

- Pressure Range: 1

- Units: bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: EPDM

- Cable Type: TPE (125degC max)

- Cable Length: 5

- Cable Length Units: Metres (m)

763-D049-1-1-2-1-1-4-3-007-000

- SKU ID: s1-lmk458-0019

- Part No: 768-D049-1-1-2-1-1-4-2-007-000

- Pressure Range: 0.8 to 1.4

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 7

- Cable Length Units: Metres (m)

760-1001-1-1-2-1-1-4-3-008-000

We need a replacement level sensor with the following part number LMK457-760-1001-1-1-2-1-1-4-3-008-000 which is used on a ship refrigeration system?

The LMK457 is no longer available and has been replaced by the LMK458. The equivalent part number and specification to match the LMK457 you are replacing would be:

- SKU ID: s1-lmk458-0011

- Part No: 765-1001-1-1-2-1-1-4-2-008-000

- Pressure Range: 1 bar g

- Pressure Connection: Protection cap (immersible)

- Housing & Pressure Connector Material: Stainless steel 316L (standard)

- Seals exposed to media: FKM (standard)

- Accuracy: 0.25% FS BSL (standard)

- Cable Type: TPE (standard)

- Length of Cable (metres): 8

763-D290-K-1-2-1-1-4-3-009-000

- SKU ID: s1-lmk458-0020

- Part No: 768-D290-K-1-2-1-1-4-2-009-000

- Pressure Range: 0.8 to 1.8

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 9

- Cable Length Units: Metres (m)

763-D243-1-5-2-1-3-4-3-008-000

I’m searching for a hydrostatic level transmitter LMK 457 with the code 763-D243-1-5-2-1-3-4-3-008-000 0.8-2.4 bar range and a cable length of 8 meters?

The LMK 457 is an old product which is no longer manufactured. The LMK 458 is the replacement product for the LMK 457 and the equivalent part number and specification would be:

- SKU ID: s1-lmk458-0016

- Part No: 768-D243-1-5-2-1-3-4-2-008-000

- Pressure Range: 0.8 to 2.4

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: G1 1/2 male screw-in version

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: EPDM

- Cable Type: TPE-U (125degC max)

- Cable Length: 8

- Cable Length Units: Metres (m)

763-D243-1-1-2-1-1-4-3-011-000

- SKU ID: s1-lmk458-0021

- Part No: 768-D243-1-1-2-1-1-4-2-011-000

- Pressure Range: 0.8 to 2.4

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 11

- Cable Length Units: Metres (m)

763-D243-1-1-2-1-1-4-3-013-000

- SKU ID: s1-lmk458-0022

- Part No: 768-D243-1-1-2-1-1-4-2-013-000

- Pressure Range: 0.8 to 2.4

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 13

- Cable Length Units: Metres (m)

760-1001-1-1-2-1-1-4-3-008-000

What is the specification configuration for LMK457-760-1001-1-1-2-1-1-4-3-008-000?

The LMK 457 has been replaced by the LMK 458 and the equivalent specification and part number is:

- SKU ID: s1-lmk458-0010

- Part No: 765-1001-1-1-2-1-1-4-2-008-000

- Pressure Range: 1 bar g

- Pressure Connection: Protection cap (immersible)

- Housing & Pressure Connector Material: Stainless steel 316L (standard)

- Seals exposed to media: FKM (standard)

- Accuracy: 0.25% FS BSL (standard)

- Cable Type: TPE (standard)

- Length of Cable (metres): 8

763-D243-1-1-2-1-1-4-3-015-000

- SKU ID: s1-lmk458-0023

- Part No: 768-D243-1-1-2-1-1-4-2-015-000

- Pressure Range: 0.8 to 2.4

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 15

- Cable Length Units: Metres (m)

763-D243-K-1-2-1-1-4-3-013-000

- SKU ID: s1-lmk458-0024

- Part No: 768-D243-K-1-2-1-1-4-2-013-000

- Pressure Range: 0.8 to 2.4

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 13

- Cable Length Units: Metres (m)

763-D291-K-1-2-1-1-4-3-018-000

- SKU ID: s1-lmk458-0025

- Part No: 768-D291-K-1-2-1-1-4-2-018-000

- Pressure Range: 0.8 to 3.3

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 18

- Cable Length Units: Metres (m)

Product Help

0.1% Accuracy

Is it possible to achieve an accuracy of 0.1% or +/- 0.01 metres in the range of 0 to 10 metres?

There is the option for improved accuracy of 0.1%, but bear in mind this only covers room temperature operation, so there will also be some temperature errors to consider as well of 0.1% FS/ 10K.

Since this is a hydrostatic measurement device, it measures pressure, so if the water density changes, the calibration to water level will also change slightly.

This sensor is calibrated in either meters of freshwater or bar, but not in metres of seawater, so normally customers specify the range in bar to prevent confusion, and use a conversion factor to the equivalent seawater level range.

Another source of errors is long term stability, which is ~ 0.1% per annum, which is a common figure quoted by most manufacturers for pressure sensing technologies. therefore checking of calibration at regular intervals is recommended depending on the level of accuracy required.

Encapsulated with no external controls

Are all the electronics are encapsulated within the sensor with no external controls?

Yes on the the standard LMK 458 all the electronics are internal to the sensor, and everything is fixed with no access for adjustment.

If you want a sensor that has a user adjustable output, we would suggest the LMK458H HART communications version, which allows you to connect a HART communication device to the 4-20mA analogue signal wires in order to communicate with the sensor and make adjustments.

Forepeak water ballast tank level

I’m looking to replace a submersible level sensor used in a forepeak water ballast tank, the part number is 763-D290-K-1-2-1-3-4-3-010-000?

This part number belongs to the LMK 457 which has been discontinued from manufacture and replaced by the LMK 458, and the corresponding like for like part number and specification is:

- SKU ID: s1-lmk458-0015

- Part No: 768-D290-K-1-2-1-3-4-2-010-000

- Pressure Range: 0.8 to 1.8

- Units: bar

- Reference Type: Absolute / Non-Vented (0 to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with flush diaphragm and detachable nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: EPDM

- Cable Type: TPE-U (125degC max)

- Cable Length: 10

- Cable Length Units: Metres (m)

Cable compatibility

What types of liquids found on a ship are compatible with the sensor cable?

The standard TPE-U cable supplied with the LMK 458 is resistant against salt water, sea water, heavy oil and has increased resistance against oil and gasoline. The cable is also flame-resistant and halogen free.

Range adjustment

Is it possible to adjust output and to measure a different liquid level range?

The standard LMK458 has a factory set fixed range output which cannot be to re-scaled by the user to a lower range. However, it is possible with the derivative LMK458H, which can be rescaled to a maximum turndown of 10:1 via the HART communication interface. You will also need a universal HART communicator in order to access and adjust the range settings.

Cable diameter

What is the diameter of the cable?

The cable diameter is 7.4mm

Cable bend radius

What is the bend radius of the cable?

A minimum static bending radius has to be complied with. For static installation rhe bend radius should be no smaller than 10 times the cable diameter. For dynamic applications the bend radius should be no smaller than 20 times the cable diameter.

F.W./T.W tank level system

I am looking for a replacement hydrostatic level transmitter for a fresh water and treated water tank level system on an ocean going vessel, the part number is 760-5910-1-3-2-1-1-4-3-004-DN50/PN40?

This is for a LMK 457 which is no longer manufactured. The LMK 458 equivalent would be as follows:

- SKU ID: s1-lmk458-0013

- Part No: 765-5910-1-3-2-1-1-4-2-004-000 / ZSF5040

- Pressure Datum: Gauge

- Pressure Range: 0 – 591 mbar

- Housing Material: Stainless Steel 1.4571 (316Ti)

- Type of Construction: Flange Version

- Diaphragm: Ceramic Al2O3, 96%

- Output: 4 – 20mA / 2-wire

- O Ring Seals: FKM

- Electrical Connection: TPE Cable

- Accuracy: 0.25%FS

- Cable Length: 4 metre TPE

- Special Options: None

- Supply Voltage: 9 – 32V dc

- Thermal Errors (TZS & TSS): 0.01% FSO / °C

- Media Temperature: -25 to +125°C

- Approvals: Germanischer Lloyd (GL) & Det Norske Veritas (DNV)

- Optional Extras: DN50/PN40 mounting flange (ZSF5040)

Ship hull diesel fuel tank level

I have a marine vessel application where I need to measure the diesel fuel level via hydrostatic pressure in a non-symmetrical tank which is made up from voids in the ships hull that are linked together and act like a fuel tank. The tank holds approximately 8600 litres of diesel fuel oil. Would the LMK 458 level transmitter be capable of meeting these needs, and does it matter if the tank is vented or not vented?

Yes the LMK 458 will work for the application you have in mind, but whether the tank is vented or not, will matter to how many sensors you need and the measurement range:

- Vented Tank – If vented then you can use a single sensor to measure the hydrostatic pressure.

- Non-Vented Tank – For a non-vented tank you would need to measure using two sensors one at the bottom and one at the top and subtract the two readings to determine the hydrostatic pressure.

LMK 457 replacement

Is the LMK458 the replacement for the LMK457?

Yes the LMK457 is no longer available and has been replaced by the LMK 458. If you are looking to replace the LMK457 you can send us the part number and we will convert it to the equivalent LMK458 part number for you.

120°C fuel

Is the LMK458 suitable for use with marine fuel, which can have a storage temperature of up to 120degC?

The LMK458 has a media operating temperature range of -25 to +125 degC if specified with the TPE coated signal cable.

Towed underwater vehicles

I need a depth sensor for towing behind an offshore survey vessel to monitor depth of a towed underwater vehicles. The range of depth will be 0-3 metres.

We would suggest the following LMK458 options:

- SKU ID: s1-lmk458-0002

- Pressure Range: 0-6

- Units: mH2O

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE (125degC max)

- Cable Length: 10

- Cable Length Units: Metres (m)

Minimum absolute and sealed gauge range

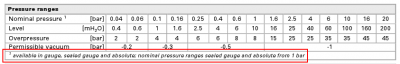

On the LMK458 marine approved submersible pressure sensor product data sheet it says that the sensor is “available in gauge, sealed gauge and absolute; nominal pressure ranges sealed gauge and absolute from 1 bar”. Does this mean the range is actually 1 to 11 bar absolute for example, and therefore they are just sealed gauge ranges with different markings, or do the available ranges start from 0 to 1 bar and upwards?

It means that the absolute and sealed gauge pressure ranges are only available from 0 to 1 bar and above.

Brine tank level measurement on offshore supply ship

We need to replace a level sensor on a brine tank aboard an offshore supply ship with part number 760–2501–K–5–2–1–1–2–3–003–546?

This is an obsolete part number belong to an old product type called the LMK457. However there is an equivalent like for like part number to same configuration which is detailed below:

- SKU ID: s1-lmk458-0012

- Part No: 765-2501-K-5-2-1-1-2-2-003-546

- Pressure Datum: Gauge, in bar

- Pressure Range: 0 – 2.5 bar

- Housing Material: Copper-Nickel-Alloy (CuNi10Fe1Mn)

- Type of Construction: Screw-in Version

- Diaphragm: Ceramic Al2O3, 96%

- Output: 4 – 20mA / 2-wire

- O Ring Seals: FKM

- Electrical Connection: PUR Cable

- Accuracy: 0.25% FS

- Cable Length: 3 metre PUR

- Special Options: Pressure port with FFKM

- Supply Voltage: 9 – 32V dc

- Thermal Errors (TZS & TSS): 0.01% FSO / °C

- Media Temperature: -25 to +125°C

- Approvals: Germanischer Lloyd (GL) & Det Norske Veritas (DNV)

Housing protection in seawater to depth of 70 metres

I need a deep sensor to measure down to 70 m depth in sea water for an offshore application. It will be attached to a metallic structure at the mentioned depth, and the metal structure will move , that’s why I need to know the depth.

The LMK 458 sensor seems to be suitable for use offshore and with sea water, but it is not clear to me about the housing, since the whole sensor and housing will be handling the pressure, we want to be sure that the housing will also support the sea water depth in all the variations, as a probe, screw, and flange connections?

Yes you can submerge the whole sensor to the required depth in seawater in any of the mounting configurations. The electrical connection is sealed to IP68 and rated to at least 200 metres.

- SKU ID: s1-lmk458-0001

- Part No: 765-7001-K-1-2-1-1-4-2-100-000

- Pressure Range: 0 to 70

- Units: mH2O

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Copper Nickel Alloy (seawater compatible)

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE (125degC max)

- Cable Length: 100

- Cable Length Units: Metres (m)

Fuel tank level sensor

We have fuel tank on a ship for which we need to replace the level sensor with part number 760-6000-1-1-2-1-1-4-3-015-000, is this still available?

This is an old part number belonging to the LMK457 which is now discontinued, and has been superseded by the LMK458. The new part number and related configuration is shown below:

- SKU ID: s1-lmk458-0014

- Part No: 765-6000-1-1-2-1-1-4-2-015-000

- Pressure Range: 0.6

- Units: bar

- Reference Type: Gauge / Vented (atm to +P)

- Output Signal: 4 to 20 mA, 2 wire

- Accuracy: 0.25% FS

- Installation Type: Probe version with nose cone

- Housing Material: Stainless Steel 316L

- Diaphragm Material: Ceramic Al2O3 96%

- Media Exposed Seals: FKM

- Cable Type: TPE-U (125degC max)

- Cable Length: 15

- Cable Length Units: Metres (m)

Related Documents

Specification data sheets

Request Product Price

Please select the options you require for the LMK458 Marine Approved Hydrostatic Level Transmitter in your application and request a quote.